Knowledge, Technology

Which type of aluminum welding wire is suitable for MIG?

In the metal fabrication industry, MIG (Metal Inert Gas) welding is widely applied due to its uniformity and high welding speed. For aluminum – a metal sensitive to temperature, choosing the right type of MIG welding wire plays a crucial role in determining the quality of the weld. In this article, we will delve into: Which type of aluminum welding wire is suitable for MIG?

What is MIG welding?

MIG welding (or GMAW – Gas Metal Arc Welding) is a welding method using a continuous wire electrode and shielding gas. A prominent feature of MIG welding is the use of a direct current electrode positive (DCEP) power source, which creates a stable and easily controllable arc.

In aluminum welding, MIG is particularly suitable due to its ability to create beautiful welds, reduce spatter, and achieve fast execution speeds. However, to achieve optimal results, it requires selecting the correct welding wire as well as the appropriate shielding gas.

Why is it necessary to choose the correct type of aluminum welding wire?

Aluminum is a light metal with a very durable surface oxide layer and a melting point lower than that of the oxide layer, which causes difficulties during the welding process. If the wrong type of welding wire is used, the weld will be prone to hot cracking, uneven penetration, or failure to meet mechanical and physical standards.

An unsuitable welding wire can also cause porosity, severe oxidation, or discoloration after welding. Therefore, choosing the correct welding wire helps ensure:

- High mechanical strength of the weld

- Bright and aesthetically pleasing weld

- Minimization of hot cracking and porosity

- Time and maintenance cost savings

Classification of MIG aluminum welding wires

1. ER4043 aluminum welding wire

ER4043 welding wire is made from an aluminum-silicon alloy with about 5% Si, providing good flowability, low viscosity, and ease of operation. It is often used to weld aluminum alloys such as 3003, 6061, 6063.

Outstanding advantages:

- Bright weld with less oxidation

- Good crack resistance under normal working conditions

- Easy to operate, suitable for beginners

Limitations

- Lower tensile strength of the weld compared to ER5356

- Not recommended for environments requiring painting (due to silicon affecting paint adhesion)

2. ER5356 aluminum welding wire

This type of welding wire contains about 5% magnesium (Mg), making it very suitable for welding high-Mg aluminum alloys such as 5052, 5083, 5356, 5454, 5554…

Advantages:

- Higher mechanical strength compared to ER4043

- Good corrosion resistance, especially in marine environments

- Bright and easy-to-polish weld

Disadvantages:

- Prone to hot cracking if welded with high-Si aluminum

- Requires appropriate current adjustment to avoid defects

How to choose the right MIG welding wire for aluminum?

1. Based on the type of aluminum alloy

Each aluminum alloy series has different chemical compositions and mechanical properties. Therefore, the choice of welding wire must be based on the material type:

- High-silicon aluminum: choose ER4043

- High-magnesium aluminum: choose ER5356

Note: Do not mix different types of welding wires without checking compatibility, as this can cause chemical reactions and reduce weld quality.

2. Based on product application

- Engineering structures (ships, containers, cranes…): prioritize ER5356 due to its high strength

- Consumer goods, interior decoration: ER4043 for beautiful welds

- Thin, high-precision parts: choose ER4043 for easier weld control

3. Suitable shielding gas

MIG welding of aluminum absolutely requires shielding gas. Pure Argon gas (99.99%) is the most common. However:

- For thick aluminum, 25–75% Helium can be mixed to increase arc energy

- Avoid using CO₂ as it will oxidize the weld and create porosity

4. Welding wire size

The diameter of the welding wire determines the amount of deposited metal and the ability to control the weld:

- 0.8mm wire: used for material <3mm

- 1.0–1.2mm wire: used for material from 3–6mm

- ≥1.6mm wire: used for thick structures requiring deep penetration

Some notes when MIG welding aluminum

Choose the correct wire feed roller

Since aluminum wire is soft and easily deformed, use a U-groove roller instead of a V-groove roller. This reduces friction and prevents wire flattening during feeding.

Welding wire storage

Aluminum welding wire easily absorbs moisture, leading to porosity. Therefore, it is recommended to:

- Store wire in sealed packaging or a moisture-proof box

- Do not expose wire directly to humid air for more than 8 hours

Use specialized liners

The wire liner for aluminum welding should be made of Teflon or soft nylon,avoid using steel tubes as they can abrade the wire's surface layer and increase friction.

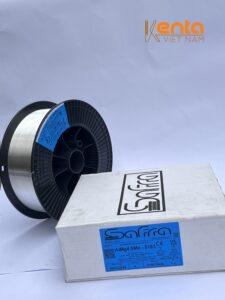

Suggestions for some good aluminum MIG welding wire products

- ER4043 Sialon 1.0mm: For common aluminum welds, easy to use and cost-effective.

- ER5356 Kobelco 1.2mm: Specifically for aluminum structures requiring strength and corrosion resistance.

Conclusion

Choosing the right aluminum welding wire for MIG depends not only on the wire type but also on the base alloy, material thickness, and technical requirements of the product. A correct choice will help achieve quality welds, extend product lifespan, and optimize production costs.

Do you need in-depth technical consultation? Don't hesitate! Contact Kenta VietNam immediately for support in choosing the right welding wire for all types of MIG aluminum welding applications!