Knowledge, Technology

How to choose the correct aluminum welding wire diameter?

Choosing the correct aluminum welding wire diameter is not just a matter of "using what you have". Choosing incorrectly can lead to poor welds, wasted materials, and delayed progress. At Kenta VietNam, we always advise customers: choosing correctly from the start is the most effective way to optimize construction efficiency.

Why should you care about aluminum welding wire diameter?

Someone new to the profession once said: "Any wire is a wire, as long as it works!" On the surface, it sounds reasonable, but in reality, aluminum welding wire is not that simple. The diameter of the aluminum welding wire directly affects the heat generated during welding, the ability to control the metal's flow, the depth of the weld, and of course – its aesthetic appeal.

For example, if you are welding a thin aluminum sheet but use a wire that is too large, it can easily cause burn-through, resulting in a weld that is both unsightly and weak. Conversely, for thick parts, a wire that is too small will not provide enough "heat", causing the weld to not fuse properly, leading to porosity and peeling. Therefore, choosing the wrong wire diameter is like using a small knife to cut a large log – it's both exhausting and ineffective.

Important factors when choosing aluminum welding wire diameter

The first thing to consider is the material thickness. The thicker the aluminum, the larger the diameter of the welding wire you need to generate enough heat to melt the material. For thin aluminum, it's the opposite – you need a small wire and a light touch to avoid "burning" through the surface.

Next is the welding current. Each wire diameter only works well within a certain current range. For example, a small 0.8mm wire is suitable for welding currents from 60–130A, while a 1.2mm wire may require 220A or more. Using the wrong current level will result in unstable welds and prone to defects.

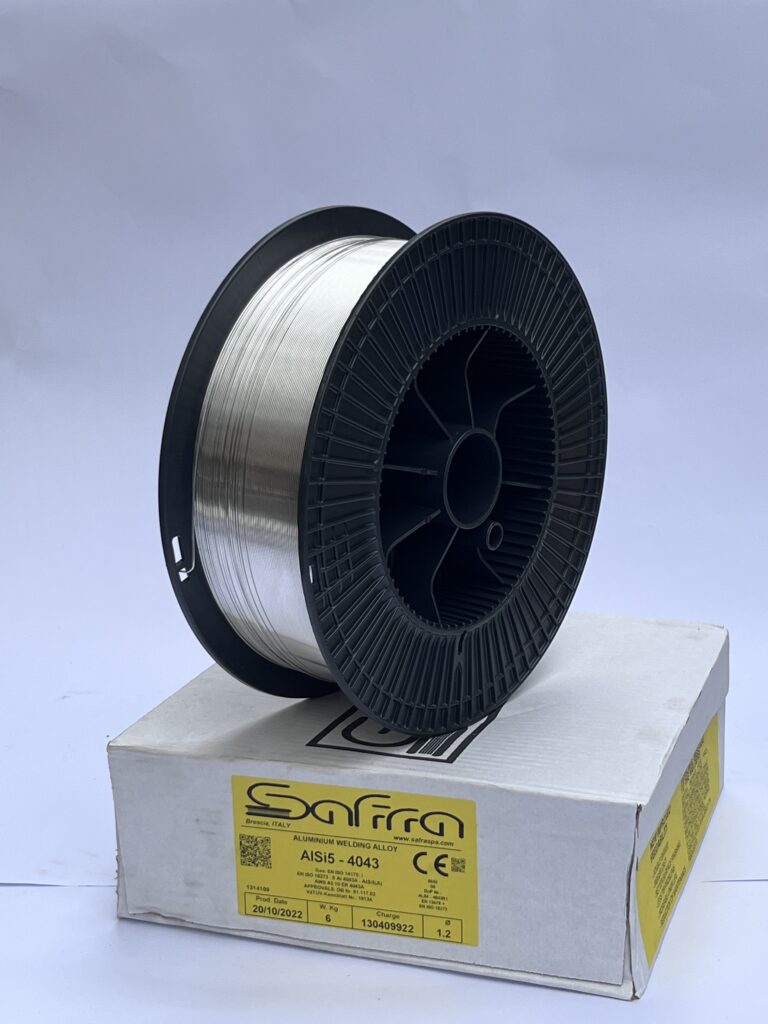

The welding machine and type of welding wire are also factors to consider. For aluminum MIG welding, the most common wires currently are ER4043 and ER5356 with diameters of 0.8mm, 1.0mm, and 1.2mm. The higher the machine's power, the larger the wire it can use – and with that comes more stable welding efficiency.

Finally, you must clearly define the product goal: If you need thin, beautiful welds that require high aesthetics (for example, in furniture or design products), a small wire will be the ideal choice. But if welding frames, technical parts, requiring high load-bearing capacity, then a large wire is mandatory.

Guide to choosing aluminum welding wire for each situation

If you are welding thin aluminum (under 2mm) – such as casing, decorative materials, aluminum cladding – then a 0.8mm wire diameter is a safe choice. Welding slowly, steadily, using a TIG or MIG AC/DC machine will help you achieve a bright, neat weld without deformation.

For aluminum 2–5mm thick – a common thickness in the manufacture of aluminum doors, vehicle frames, cabinet partitions – you can choose a 1.0mm or 1.2mm wire. Remember to adjust the current parameters appropriately, and use pure Argon shielding gas to avoid contamination during welding.

And if you need to weld large parts, aluminum 6mm thick or more, consider a 1.2mm or 1.6mm wire. In some special cases such as manufacturing industrial tanks or marine vessels, a 2.0mm wire may be needed – at this point, a high-power welding machine should be used to ensure efficiency.

Suggestions for popular aluminum welding wire types today

Currently, Kenta VietNam is supplying two popular and widely used aluminum welding wire types:

- ER4043 – This wire type has a high silicon content, which helps the weld be shiny, crack-resistant, and easy to work with. This is an ideal choice when welding 6xxx series aluminum alloys such as 6061, 6063.

- ER5356 – This wire has a high magnesium content, increasing its strength and excellent corrosion resistance. It is suitable for applications requiring high durability such as in the marine, automotive, or heavy industrial structural industries.

Chúng tôi luôn sẵn sàng tư vấn loại dây và đường kính phù hợp theo từng yêu cầu công việc cụ thể, giúp bạn không mất thời gian thử sai và tối ưu hiệu quả hàn ngay từ lần đầu tiên.

Conclusion

Whether you are new to the profession or a seasoned welder, choosing the correct aluminum welding wire diameter is always an indispensable factor. It affects product quality, completion speed, and equipment operating efficiency.

At Kenta VietNam, we not only provide high-quality welding wire but also accompany customers in every step of material selection,effective technical consulting and construction solutions. Don't let a small detail affect the entire project – choosing correctly from the start is the most economical!