Knowledge, Technology

Should you choose 4043 or 5356 welding wire for outdoor products?

When it comes to aluminum welding, the two most commonly used welding wires today are 4043 and 5356. However, if the product you’re fabricating will be used outdoors – exposed directly to rain, sun, high humidity, or even seawater – choosing the right welding wire is extremely important. So, should you choose 4043 or 5356 welding wire for outdoor products? The following article will help you understand the advantages and disadvantages of each type, so you can make the best decision for your project.

4043 aluminum welding wire with the advantage of smooth welds and easy operation

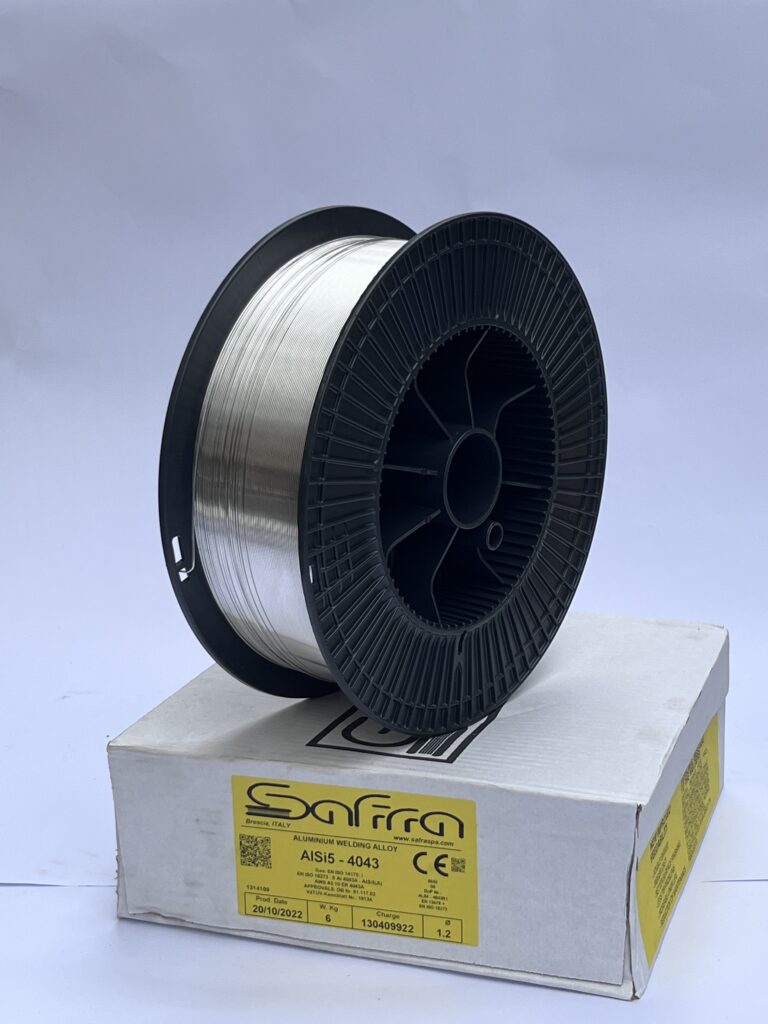

4043 welding wire is an aluminum alloy containing about 5% silicon. Thanks to this composition, this wire has good flowability, easily fills weld grooves, and produces smooth, even, shiny welds. Especially, 4043 produces little porosity, helping reduce technical defects and is suitable for both TIG and MIG welding.

One reason many people prefer 4043 is its ability to limit cracking after welding, especially when welding aluminum alloys in the 6xxx series like 6061. With easy operation and high stability, 4043 wire is often chosen for products that require high aesthetics, clear weld seams, low spatter, and easy cleaning.

However, in terms of mechanical strength and corrosion resistance in outdoor environments, 4043 still has some limitations compared to 5356 – especially under harsh conditions such as coastal areas or places exposed to chemicals.

5356 aluminum welding wire is durable and offers superior corrosion resistance

5356 welding wire contains about 5% magnesium, providing significantly higher tensile strength than 4043. This type of wire is known for its excellent strength and corrosion resistance, even in outdoor environments with high humidity, sea air, or mild chemicals.

If your product must operate under harsh weather conditions – such as aluminum scaffolding, outdoor equipment, vehicle frames, or ship hulls – 5356 is a more suitable choice. The welds created are strong, able to bear loads, resistant to oxidation, and maintain color over time.

However, 5356 wire has a minor drawback: it is more prone to cracking if used with the wrong base aluminum, especially when welding 6061 aluminum in an untreated state. Therefore, when using 5356, you need to know your base aluminum type clearly to ensure maximum compatibility.

So should you choose 4043 or 5356 welding wire for outdoor products?

If your top priority is aesthetics, ease of operation, neat welds, and minimal technical defects, 4043 welding wire is an ideal choice – especially for small details, decorative projects, or aluminum products that do not bear heavy loads outdoors.

Conversely, if you need high durability, strong corrosion resistance, and your product will have prolonged exposure to wind, rain, or harsh environments, then 5356 wire is the safer and more durable option.

In other words, your usage environment and product technical requirements will determine which welding wire to use. 4043 is good for smooth, easy welds; 5356 stands out for mechanical strength and weather resistance.

Notes when choosing aluminum welding wire for outdoor projects

Beyond just choosing between 4043 and 5356, you should also consider other factors such as material thickness, welding method (TIG or MIG), construction conditions, and the type of base aluminum in use.

Additionally, always ensure the welding wire is stored properly to avoid moisture or oxidation before welding – as this greatly affects the final weld quality, especially when used for outdoor products that require long-lasting durability.

Conclusion

So should you choose 4043 or 5356 welding wire for outdoor products? The answer depends on your specific needs and conditions. 4043 is easy to use and produces beautiful welds; 5356 is strong and effectively corrosion-resistant. Choosing the right type will help your product last longer, save maintenance costs, and ensure safety during use.

If you need more detailed advice on selecting aluminum welding materials suitable for your construction conditions, contact Kenta VietNam – a unit specializing in providing genuine aluminum welding wire with full CO CQ.Technical support with dedication and a nationwide warehouse network. We are ready to accompany every outdoor project – whether residential or industrial!