SAFRA SF-CuSi3/ ER CuSi-A Copper Welding Wire Spool

SAFRA SF-CuSi3/ ER CuSi-A Copper Welding Wire Spool

Contact

SAFRA SF-CuSi3 / ER CuSi-A Copper Welding Wire Spool – An effective welding solution for copper alloys and galvanized materials

SAFRA SF-CuSi3 / ER CuSi-A is a copper-silicon alloy welding wire specifically designed for inert gas arc welding (TIG & MIG) of copper-based materials such as copper-silicon, copper-zinc, and galvanized steel sheets. The product also effectively connects copper to steel, meeting diverse construction needs in various fields such as mechanical engineering, metallurgy, and structural industries. This is an ideal choice for engineers and welders who require strong, aesthetically pleasing, and corrosion-resistant welds.

SAFRA SF-CuSi3 / ER CuSi-A Copper Welding Wire Spool – An effective welding solution for copper alloys and galvanized materials

SAFRA SF-CuSi3 / ER CuSi-A is a copper-silicon alloy welding wire specifically designed for inert gas arc welding (TIG & MIG) of copper-based materials such as copper-silicon, copper-zinc, and galvanized steel sheets. The product also effectively connects copper to steel, meeting diverse construction needs in various fields such as mechanical engineering, metallurgy, and structural industries. This is an ideal choice for engineers and welders who require strong, aesthetically pleasing, and corrosion-resistant welds.

Suitable for artistic welding and anti-corrosion surface coating

With its high bonding and finishing capabilities, CuSi3 / ER CuSi-A welding wire is often used in artistic foundries to repair and secure intricate cast copper details. Additionally, the product is applied as a protective anti-corrosion coating on steel surfaces, extending the lifespan of equipment in harsh environments. Its smooth, clean, and stable welding capability makes it an indispensable tool in both industrial and artistic fields.

Optimized for MIG and TIG welding – Versatile, durable, easy to use

Dây hàn SAFRA SF-CuSi3 welding wire is perfectly compatible with both MIG and TIG welding methods, providing high flexibility during construction. Thanks to its optimized alloy formula, the welds achieve high stability, are porosity-free, and have superior corrosion resistance. This is an ideal product for projects requiring high precision, good aesthetics, and long-term environmental resistance.

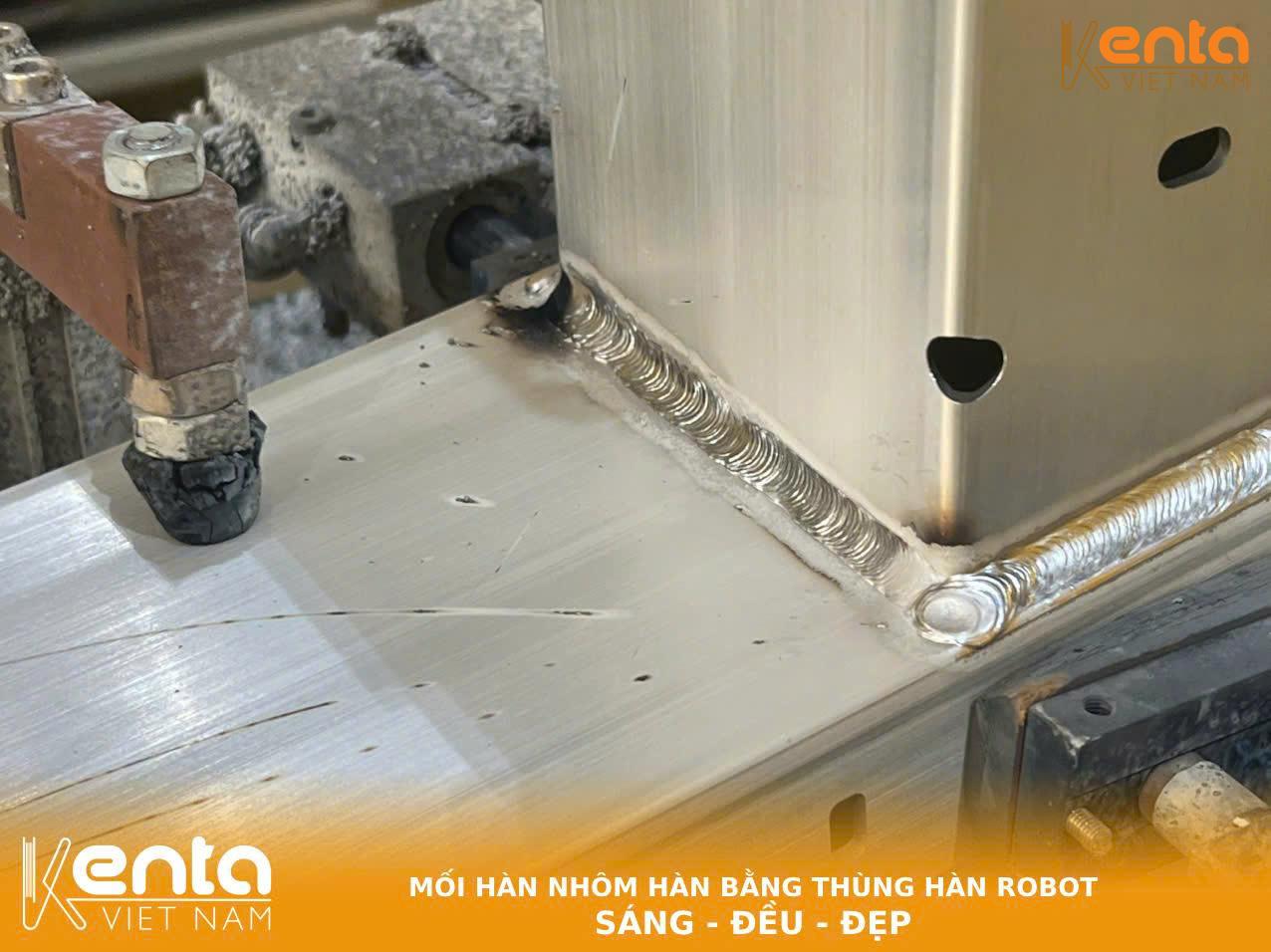

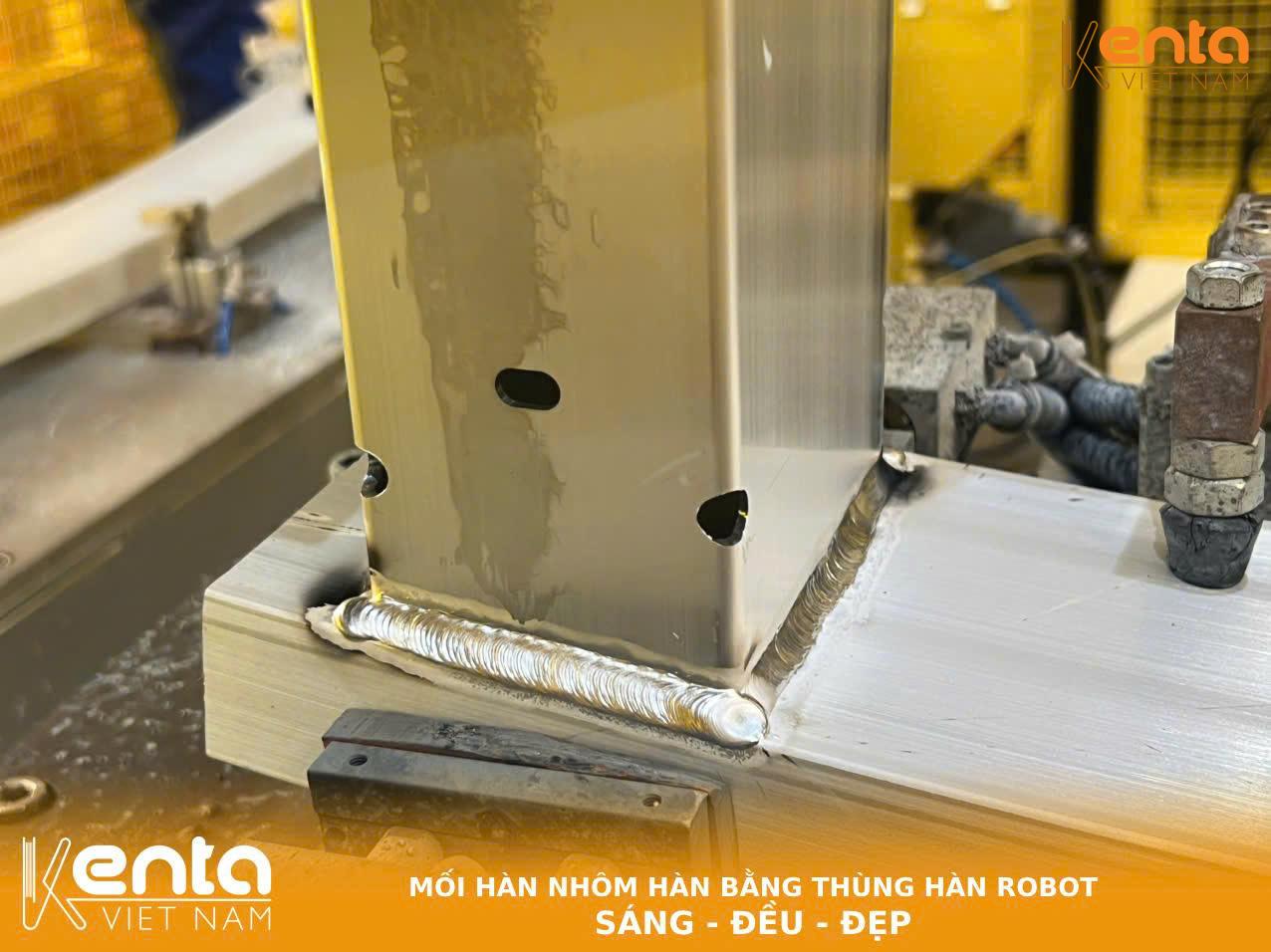

Kenta Vietnam guides customers on installing copper welding wire drums for robot welding

Welding robot using Safra copper welding wire drum from Kenta Vietnam

Be the first to review “Thùng dây hàn đồng SAFRA SF-CuSi3/ ER CuSi-A”

Reviews

There are no reviews yet.