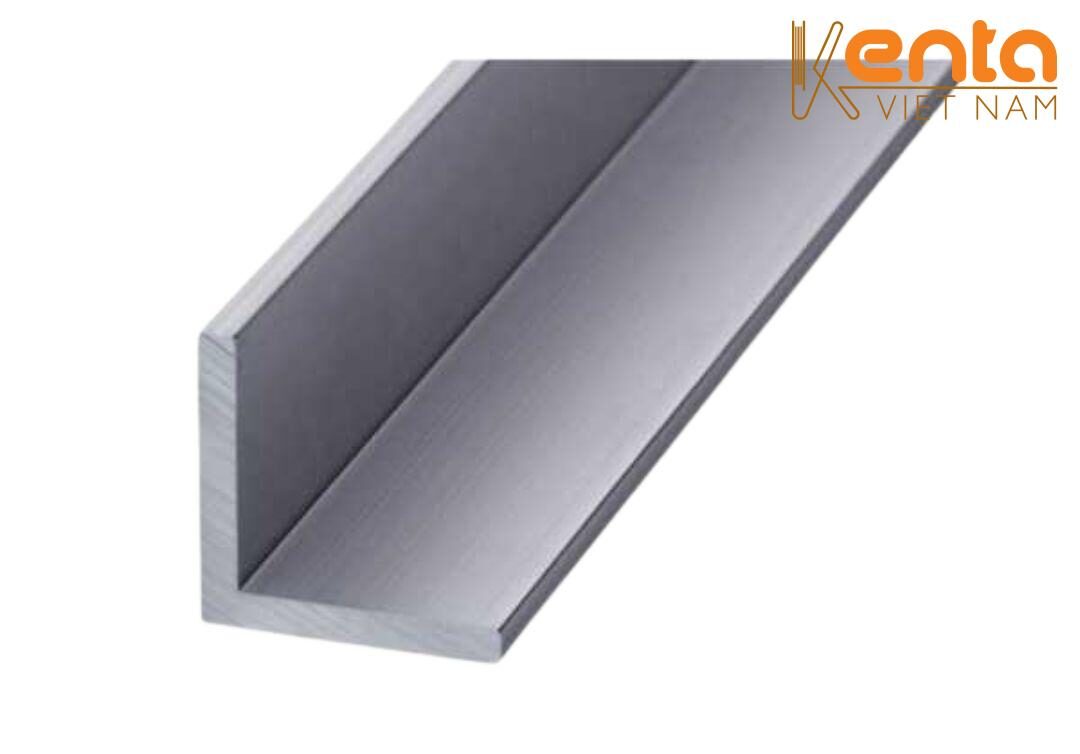

L-shaped aluminum bar

L-shaped aluminum bar

Contact

-

Features: L-shaped design, sturdy right-angle structure, good load-bearing capacity and stability, lightweight, smooth surface, easy to process and install.

-

Applications: Used as corner protectors, structural frames, decorative trims, door frames, brackets, machinery manufacturing, furniture, and construction items.

-

Certification: Fully VR registered.

-

Price: Guaranteed best market price compared to products of the same quality.

What is an L-shaped aluminum bar?

An L-shaped aluminum bar (also known as L-angle aluminum) is an aluminum product with an L-shaped cross-section, primarily manufactured by extrusion from raw aluminum or specialized aluminum alloys. Thanks to its 90° right-angle structure, the L-shaped aluminum bar offers good load-bearing capacity and high stability while retaining the characteristic light weight of aluminum, making it widely applicable in construction, mechanical engineering, and many industrial fields.

Characteristics of L-shaped aluminum bar:

-

Light and durable: Much lighter than steel, but still ensures good mechanical strength, suitable for light and medium load-bearing structures.

-

Corrosion resistance: The natural oxide layer helps protect the surface, effectively preventing oxidation and corrosion, especially in humid or coastal environments.

-

Easy to process: Can be cut, drilled, welded, and surface treated (painted/anodized) as required.

-

Good electrical and thermal conductivity: Suitable for specific technical applications.

-

High aesthetics: The surface can be polished, anodized, or powder coated, enhancing aesthetics and color durability.

Applications of L-shaped aluminum bar:

-

Construction: Used as corner protectors, structural frames, decorative trims, door frames, partitions.

-

Mechanical engineering: Used in machine manufacturing, equipment frames, brackets.

-

Electrical – electronics industry: Used as electrical conductors, equipment mounting frames.

-

Marine and shipbuilding: Used for load-bearing and corrosion-resistant components in marine environments.

-

Furniture and decoration: Used as protective trims, display frames, shelves, and household items.

Common aluminum alloy grades used for L-shaped aluminum bars:

-

Aluminum 6061: High strength, good corrosion resistance, easy to process, used for load-bearing structures.

-

Aluminum 6063: Smooth surface, high aesthetic appeal, easy to anodize, common in construction.

-

Aluminum 5052: Good corrosion resistance, suitable for marine environments.

-

Aluminum 1100: Nearly pure aluminum, soft, easy to bend, used for light and decorative applications.

-

Aluminum 7075: Very high hardness and tensile strength, suitable for heavy-duty applications.

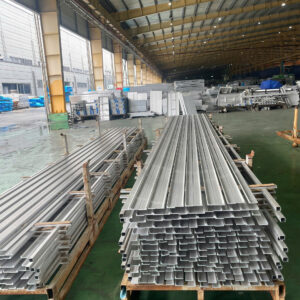

Actual images of L-shaped aluminum bars at Kenta Vietnam warehouse:

Contact information:

Be the first to review “Thanh nhôm L”

Reviews

There are no reviews yet.