Aluminum Bulb Flat

Aluminum Bulb Flat

Contact

-

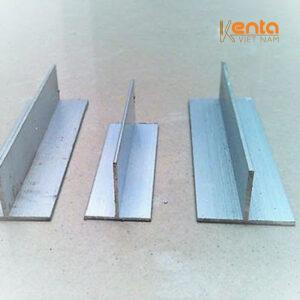

Features: Beak shape (L-shaped), lightweight, durable, corrosion-resistant, easy to cut and machine.

-

Applications: Reinforcing corners in construction, interior decoration, making door frames, support structures.

-

Full VR registration

-

Guaranteed best market price compared to products of the same quality.

Beak aluminum, also known as beak aluminum profile, is a type of aluminum profile with a special shape, having one or more sides with a "beak-like" protrusion, often used in applications requiring anti-slip properties or structural reinforcement.

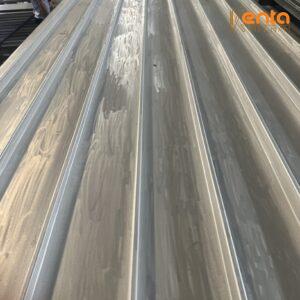

Beak aluminum drawing:

1. Features of beak aluminum:

- Anti-slip: The surface of beak aluminum often has patterns or grooves to enhance grip and prevent slipping.

- Durable and lightweight: Beak aluminum is lightweight but very durable, with good corrosion resistance due to its natural oxide layer.

- Easy to process: Can be easily cut, welded, and machined according to specific requirements.

- High aesthetic appeal: Can be surface-treated to achieve an attractive appearance and protection against corrosion.

Types of molds:

2. Applications of beak aluminum:

- Industrial floors and stairs: Used to create industrial floors, stairs, and areas requiring high grip to reduce the risk of slipping.

- Construction industry: Used as reinforcing or decorative components in construction and interior projects.

- Automotive and aerospace industries: Used in load-bearing parts requiring high anti-slip properties.

- Outdoor equipment: Beak aluminum is also suitable for outdoor applications due to its weather and corrosion resistance.

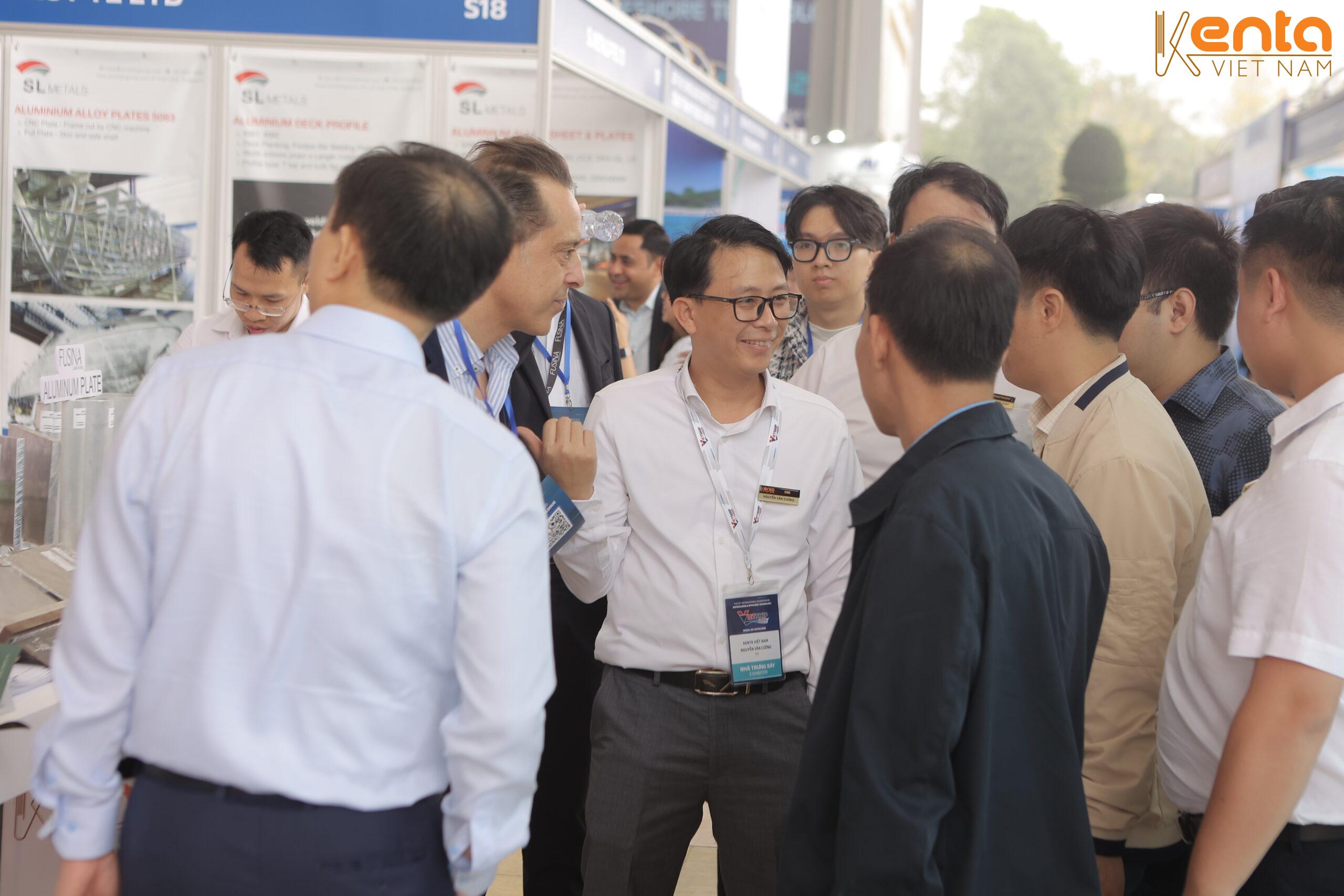

Kenta Vietnam displays aluminum at Vietship 2025 exhibition:

Below are some common aluminum alloys used in beak aluminum applications:

- Aluminum 5083:

- Features: Extremely good corrosion resistance, especially in harsh environments such as seawater and chemicals.

- Applications: Often used in offshore aluminum structures, containers, and heavy-duty components in harsh environments.

- Aluminum 6061:

- Features: High strength, easy to machine, good corrosion resistance.

- Applications: Often used for load-bearing frame components, machinery structures in mining.

- Aluminum 7075:

- Features: One of the highest strength aluminum alloys, but with poorer corrosion resistance compared to aluminum 5083 or 6061.

- Applications: Used for heavy-duty components requiring high hardness, such as shafts and mechanical parts in the mining industry.

- Aluminum 2024:

- Features: High strength, good fatigue resistance but poorer corrosion resistance.

- Applications: Used in components requiring high strength but not much exposure to corrosive environments, such as parts in mining equipment.

- Aluminum 1050:

- Features: High purity, good corrosion resistance but lower mechanical strength than other aluminum alloys.

- Applications: Used in applications requiring high electrical and thermal conductivity, with less demand for mechanical strength.

Aluminum in the mining industry must meet strict criteria for load-bearing capacity, corrosion resistance in harsh environmental conditions, and high durability to ensure efficiency and safety in mining operations.

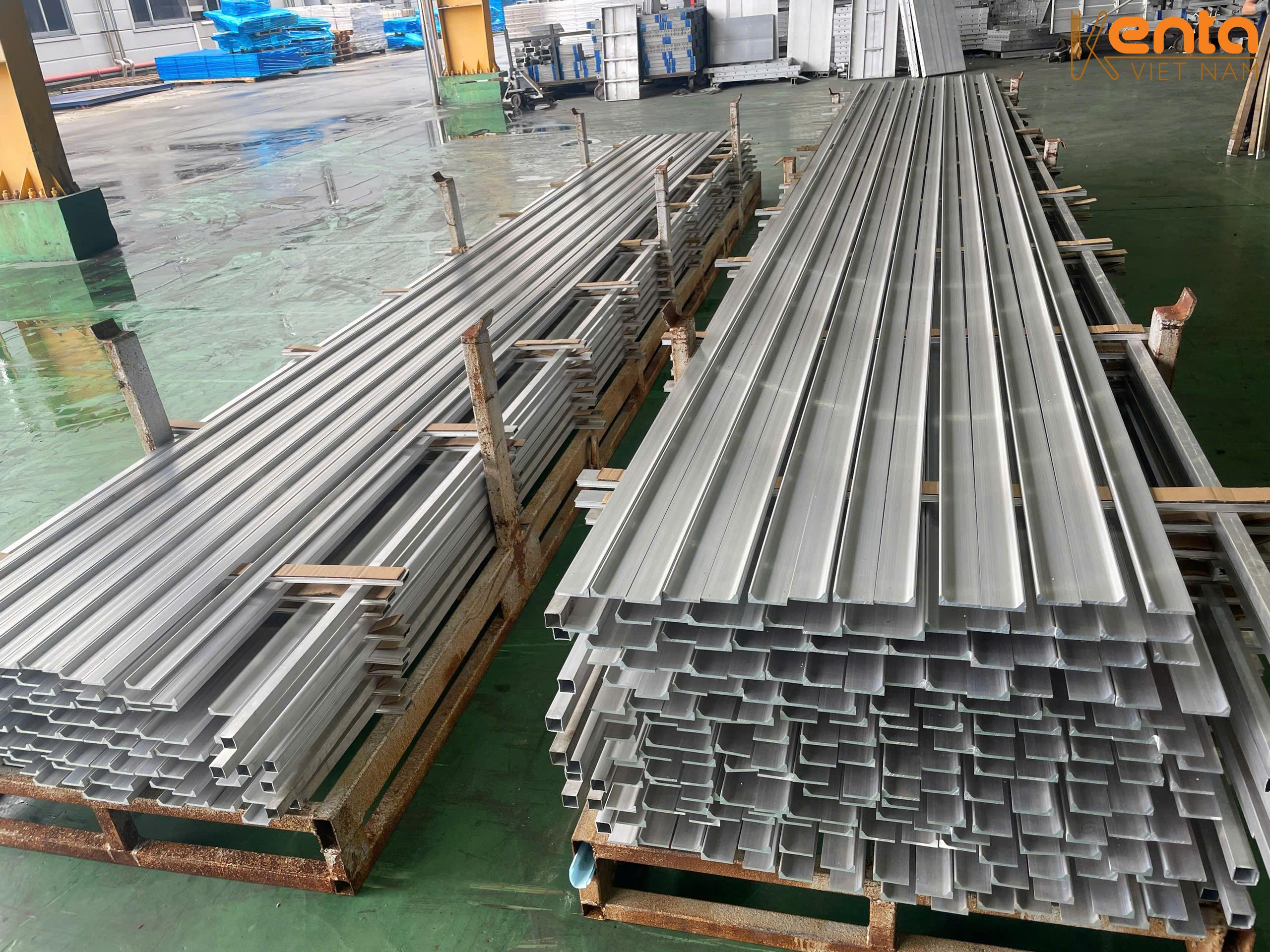

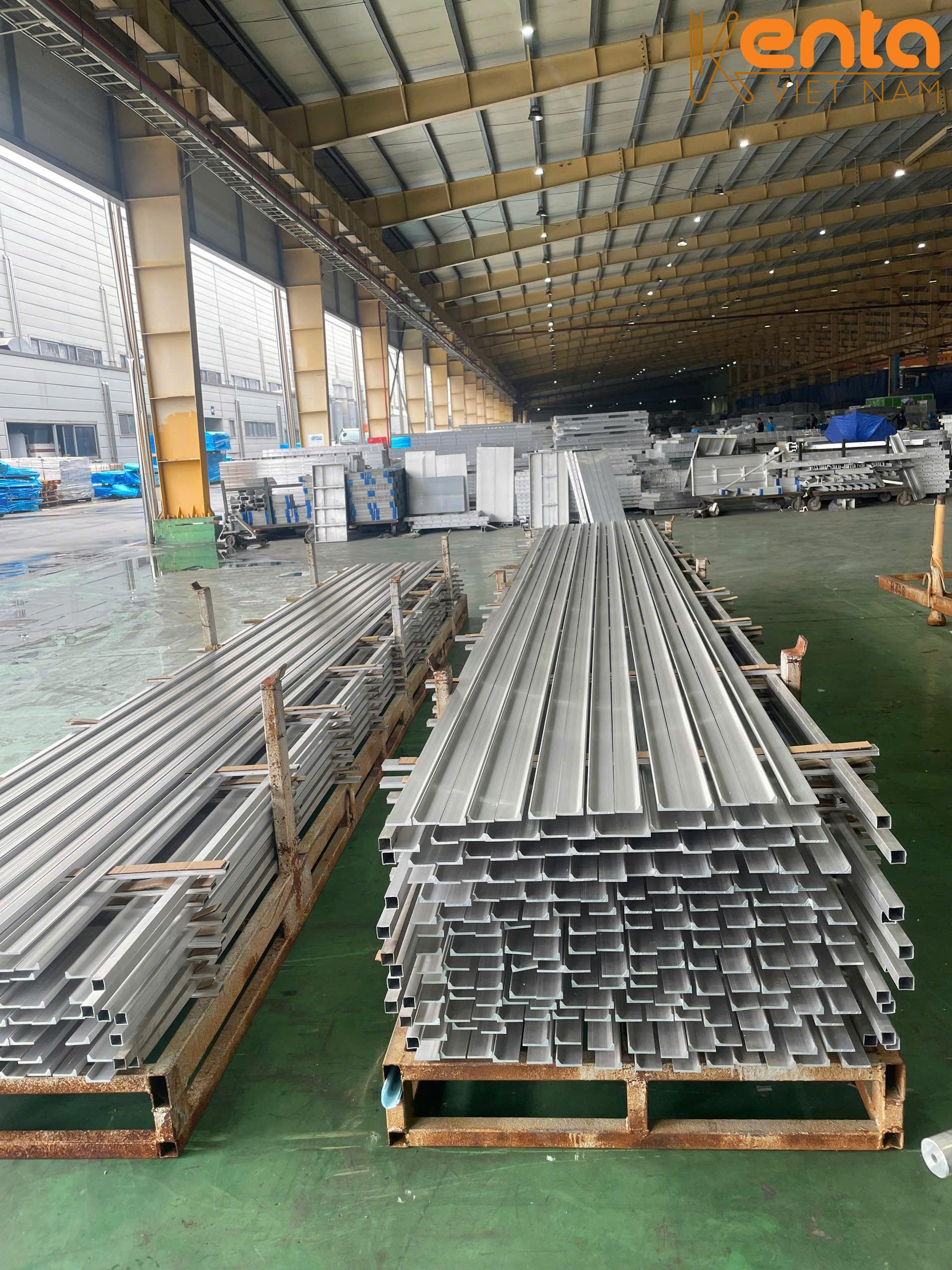

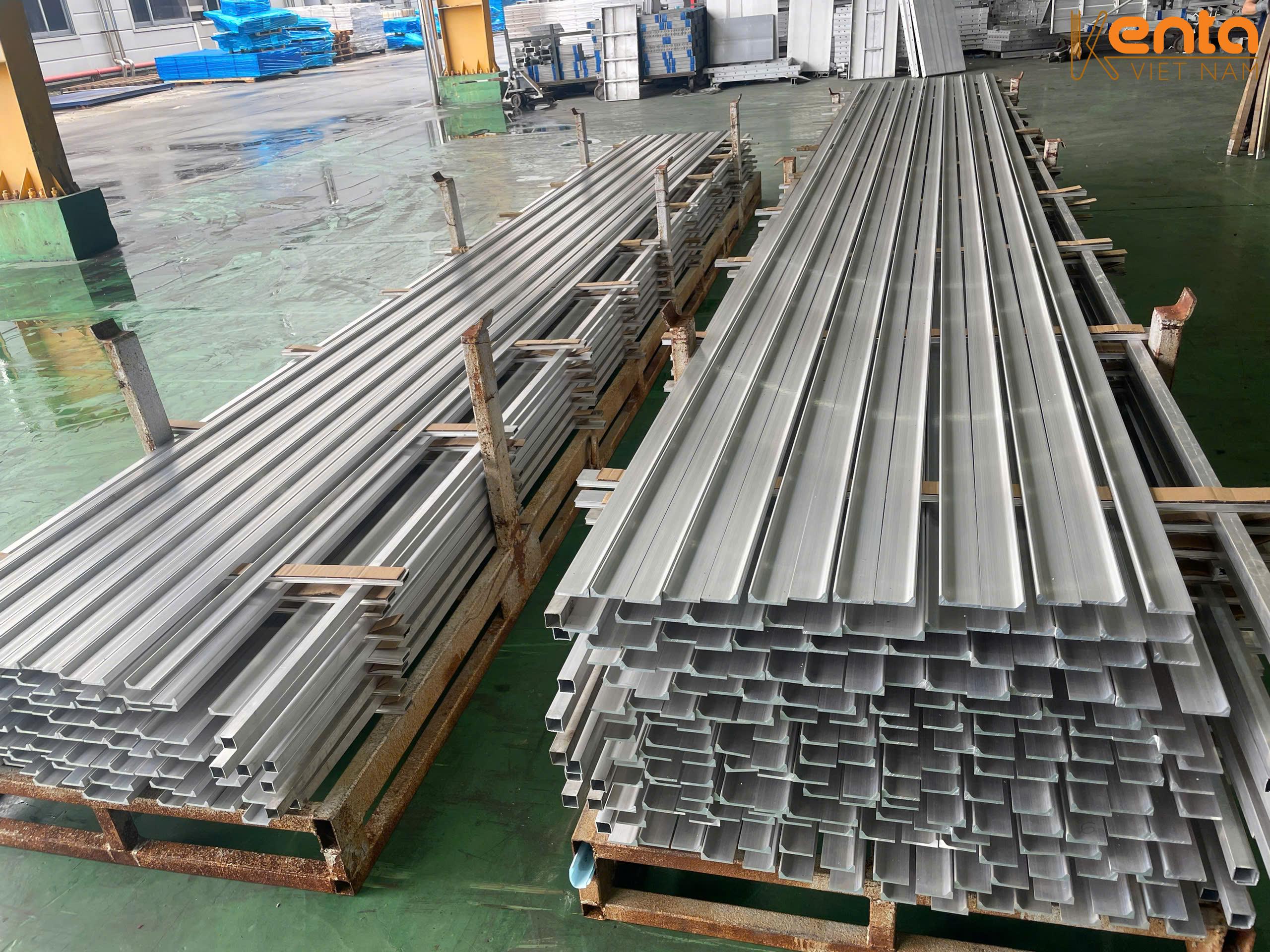

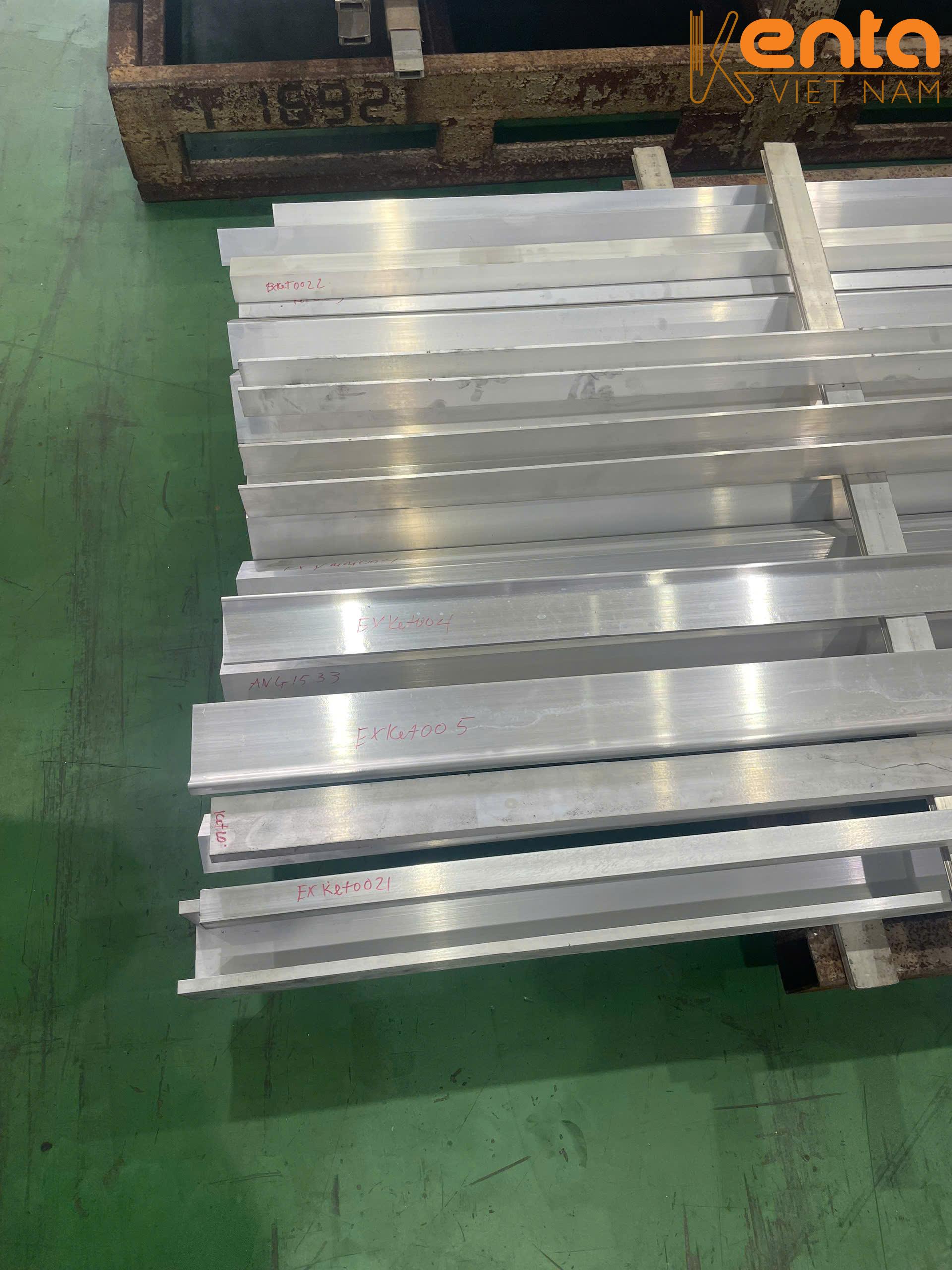

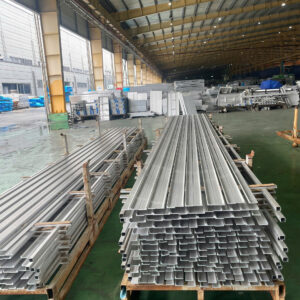

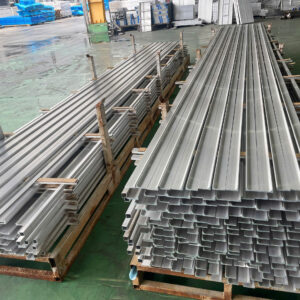

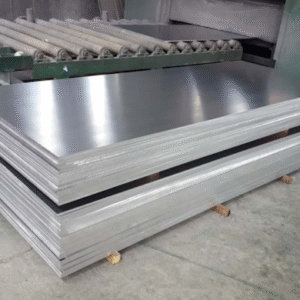

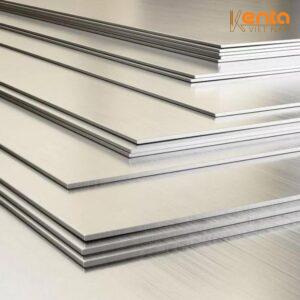

Actual images of aluminum at Kenta Vietnam warehouse:

Contact information:

Be the first to review “Nhôm mỏ”

Reviews

There are no reviews yet.