Knowledge, Technology

Popular Aluminum Alloy Types Today

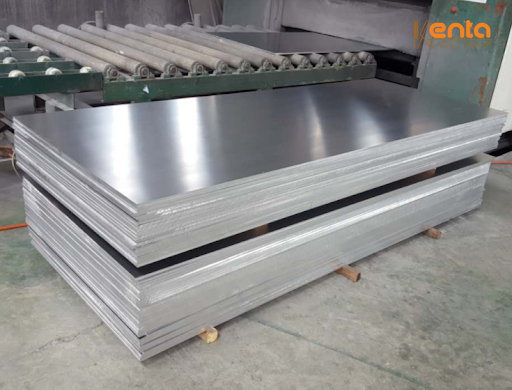

Aluminum sheet and its alloys have become the backbone of many modern industries, from construction to aerospace. The diversity of types and unique characteristics of each aluminum alloy series provide optimal solutions for specific technical requirements. This article will provide an overview of common aluminum alloy types, their distinct advantages and disadvantages, practical applications in daily life, and introduce a reliable partner in the industry Kenta VietNam.

Introduction to aluminum alloys

Definition and applications of aluminum alloys

Aluminum alloy is a material created by mixing pure aluminum with one or more other metallic elements such as copper, magnesium, silicon, zinc, manganese, or iron. The addition of these elements significantly improves the mechanical properties of pure aluminum, which is soft and difficult to process. Properties such as tensile strength, hardness, corrosion resistance, weldability, and machinability are enhanced, allowing aluminum alloy to be widely used in:

- Manufacturing:Machine components, molds.

- Construction:Structures, facades, doors, frames.

- Transportation:Vehicle bodies, aircraft skins, ships.

- Electronics:Device casings, heat sinks.

Benefits of using aluminum alloys

The use of aluminum alloy offers many outstanding benefits:

- Improved mechanical properties:Increased hardness, strength, wear resistance.

- Lightweight:Helps reduce overall weight, saving fuel in transportation.

- Corrosion resistance:Many alloys have good corrosion resistance in various environments.

- Easy to process:Good formability, cutting, and welding capabilities, suitable for many manufacturing methods.

- Recyclability:Contributes to environmental protection, reduces production costs.

Classification of aluminum alloys

Aluminum alloy are typically classified according to the international four-digit system proposed by the Aluminum Association, where the first digit indicates the main alloying element:

- 1xxx: Pure aluminum (≥99% Al).

- 2xxx: Aluminum-copper alloys.

- 3xxx: Aluminum-manganese alloys.

- 4xxx: Aluminum-silicon alloys.

- 5xxx: Aluminum-magnesium alloys.

- 6xxx: Aluminum-magnesium-silicon alloys.

- 7xxx: Aluminum-zinc alloys.

- 8xxx: Aluminum and other element alloys.

Common aluminum alloy types

Each aluminum alloy series has a unique set of characteristics, suitable for different applications.

1000 series aluminum alloys

These are the purest aluminum types (at least 99% aluminum).

- Representatives: 1050, 1060, 1100.

- Characteristics:Very soft, ductile, easy to bend, excellent corrosion resistance, and very good electrical and thermal conductivity.

- Electrical cables, aluminum foil, food packaging, decorative applications.

2000 series aluminum alloys

These are aluminum alloys with copper as the main element.

- Representatives: 2024, 2014, 2017.

- Characteristics:Very high tensile strength, hard, good heat resistance, but poorer corrosion resistance than other series.

- ApplicationsAircraft structures, aerospace components, high-load bearing parts.

3000 series aluminum alloys

These are aluminum alloys with manganese as the main element.

- Representatives: 3003, 3105.

- Characteristics:Medium strength, good corrosion resistance, easy to form and weld.

- ApplicationsKitchenware (pots, pans), containers, pipes, roofing, truck bodies.

4000 series aluminum alloys

These are aluminum alloys with silicon as the main element.

- Representatives: 4043, 4047.

- Characteristics:Low melting point, often used as welding material.

- ApplicationsWelding electrodes, welding rods, alloy casting.

5000 series aluminum alloys

These are aluminum alloys with magnesium as the main element.

- Representatives: 5052, 5083, 5754.

- Characteristics:Good strength, excellent corrosion resistance in seawater environments, good weldability.

- ApplicationsShip hulls, marine structures, tanks, oil and gas pipelines, traffic signs.

6000 series aluminum alloys

These are aluminum alloys with magnesium and silicon as the main elements.

- Representatives: 6061, 6063.

- Characteristics:High strength, good corrosion resistance, easy to form and weld, can be heat-treated.

- Applications: Window frames, doors, architectural structures, bicycle components, conduits.

7000 series aluminum alloy

An aluminum alloy with zinc as the main element.

- Representatives: 7075, 7050.

- Characteristics:Very high strength (highest among aluminum alloys), hard, but poorer corrosion resistance and weldability.

- Applications: Aircraft structures, high-stress components in aerospace, military equipment.

8000 series aluminum alloy

An aluminum alloy with elements other than those in the above groups, such as tin (Sn), lithium (Li), etc.

- Representatives: 8006, 8011 (often containing tin).

- Characteristics:Diverse depending on the alloying element, often used in special applications.

- Applications: Aluminum foil used in pharmaceutical packaging, batteries, can shells.

Advantages and disadvantages of each type of aluminum alloy

Each type of aluminum alloy has its own outstanding advantages, but also comes with some limitations that need to be considered when choosing.

Advantages of 1000 to 8000 series aluminum alloys

- Series 1000: Ductile, easy to form, good electrical/thermal conductivity, excellent corrosion resistance, low cost.

- Series 2000: Extremely high strength and hardness, suitable for high-load applications.

- Series 3000: Good formability and weldability, fair corrosion resistance, reasonable cost.

- Series 4000: Low melting point, ideal for welding and casting materials.

- Series 5000: Excellent corrosion resistance in marine environments, fair strength, good weldability.

- Series 6000: Good balance of strength, corrosion resistance, weldability, and workability, can be heat-treated.

- Series 7000: Highest strength, a top choice for ultra-strong structures.

- Series 8000: Specific properties for applications requiring unique features (e.g., batteries, packaging).

Disadvantages and limitations of each type of aluminum alloy

- Series 1000: Low strength, not suitable for load-bearing applications.

- Series 2000: Poor corrosion resistance (prone to pitting), harder to weld, requires post-weld heat treatment.

- Series 3000: Strength not as high as series 2000, 6000, 7000.

- Series 4000: Rarely used as a main structural material due to low strength.

- Series 5000: Strength may decrease at high temperatures, difficult to heat treat.

- Series 6000: Strength not equal to series 2000 or 7000 for extremely high-load applications.

- Series 7000: Poor corrosion resistance, especially stress corrosion, difficult to weld, high cost.

- Series 8000: Very specialized properties, not versatile.

Practical applications of aluminum alloys in daily life

Aluminum alloy have deeply penetrated every aspect of modern life, from familiar objects to advanced technologies.

Construction industry:

Aluminum alloy are used for door frames, glass partitions, curtain walls, decorative cladding panels, roofing systems, and support structures. In particular, alloys like 6061, 6063 with good formability and corrosion resistance are top choices.

Transportation industry

From cars, motorcycles to trains, ships, and bicycles, aluminum alloy help reduce vehicle weight, thereby saving fuel and reducing emissions. Series 5000 (for marine vessels) and 6000 (for vehicle frames) are widely applied.

Electronics and technology industry

Aluminum alloy are used for phone casings, laptops, tablets, CPU heatsinks, and other electronic components due to their good heat dissipation, light weight, and luxurious appearance.

Aerospace industry

This industry demands maximum strength and light weight, where 2000 and 7000 series aluminum alloys play an extremely important role in manufacturing aircraft bodies, wings, and main load-bearing components.

Kenta Vietnam – A reliable partner in supplying aluminum alloys

To choose the right type of aluminum alloy and ensure quality for your project, finding a reputable supplier is essential. Kenta VietNam is proud to be a reliable partner, specializing in providing diverse types of aluminum sheets and aluminum alloy , meeting all customer needs.

Introduction to Kenta Vietnam

With many years of experience in the metal industry, Kenta VietNam has affirmed its position as one of the leading aluminum alloy suppliers in the Vietnamese market. The company always strives to provide high-quality products with clear origins and meeting international standards.Kenta's Products and Services

Kenta's Products and Services

Kenta VietNam offers a rich portfolio of aluminum alloy products, including series from 1xxx to 8xxx, with various thicknesses, sizes, and shapes (such as aluminum sheets, coils, etc.). In addition, Kenta VietNam also provides custom processing services, ensuring the final product perfectly matches the customer's technical drawings.

Commitment to Quality and Reliability

Quality is the top priority at Kenta VietNam. All aluminum sheets and aluminum alloy products undergo rigorous inspection processes, ensuring they meet the most stringent technical standards. Customer trust is a testament to Kenta VietNam commitment to quality and service.

Consulting Support and Solutions for Businesses

Kenta VietNam's team Kenta VietNam is always ready to provide in-depth consultation, helping customers choose the most suitable aluminum alloy for each specific application, thereby optimizing performance and investment costs. We not only provide products but also offer comprehensive solutions for businesses.

Conclusion

Aluminum alloy Aluminum alloy is an indispensable material in many modern industries due to its superior properties and flexible applications. Understanding each type of alloy, their advantages and disadvantages, will help you make informed choices for your project. To ensure quality and receive the best support, seek out reputable partners like Kenta VietNam, where you can find a wide variety of high-quality aluminum sheets and aluminum alloy , along with professional service.