Knowledge, Technology

How to choose the appropriate aluminum sheet thickness for each application

In modern industries, aluminum sheets are a familiar material. The variety in size, thickness, aluminum grade, and technical properties allows aluminum sheets to flexibly meet different requirements. However, one of the factors that often confuses users the most is how to choose the right aluminum sheet thickness for each specific application. Choosing correctly will save costs, effort, and ensure technical efficiency. But if chosen incorrectly, you might face issues like deformation, insufficient strength, or wasteful surplus of materials.

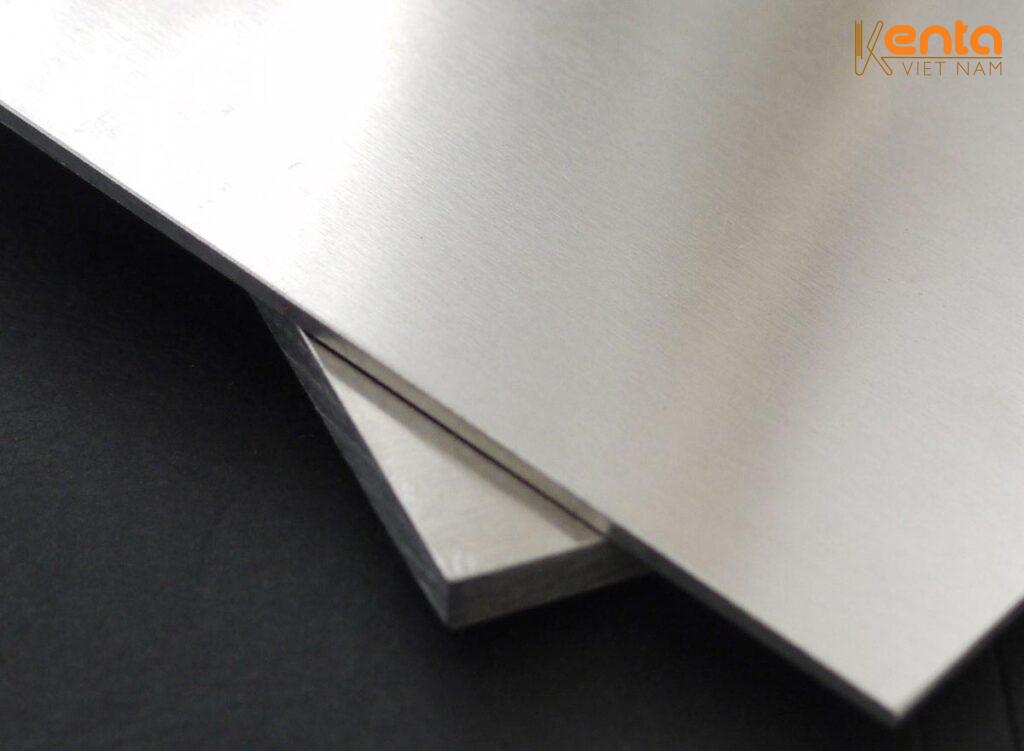

Thickness is the factor that determines the working capacity of aluminum sheets

Each aluminum sheet is not just a flat block of material but a load-bearing, corrosion-resistant, insulating, or protective foundation in technical structures. Among these, thickness plays a decisive role in load-bearing capacity, stiffness, and stability of the aluminum sheet. The same aluminum grade with different thicknesses will produce completely different results. Thin aluminum is often preferred in applications requiring lightweight and high flexibility, while thick aluminum excels in positions that bear heavy loads or need exceptional durability over time.

How do differences between applications affect the thickness?

There is no “standard” thickness that applies universally to all industries. In mechanical manufacturing, parts like molds, flanges, or machine shafts usually require aluminum with medium to very thick thickness to ensure no deformation during processing. Meanwhile, in advertising, interior design, or packaging, thin aluminum sheets dominate due to ease of shaping and material savings.

Even within an industry like shipbuilding, thickness is allocated differently for each component: the hull needs thick aluminum for load-bearing, while cabins or windows may use thin sheets to save weight. Therefore, when it comes to choosing thickness, the answer is always linked to the specific usage purpose.

The impact of working environment on aluminum thickness

Not only the application but also the usage environment greatly affects the choice of thickness. In marine environments, aluminum must withstand loads and also resist high corrosion in salty water and high humidity conditions. Thus, choosing a larger thickness combined with specialized aluminum grades will help increase the product’s lifespan. In chemical plants, aluminum needs to be thick enough to resist destruction by continuous heat or chemical reactions. On the other hand, if you are making indoor partitions or residential windows with minimal environmental impact, the thickness can be significantly smaller while still ensuring safety.

When should thick aluminum sheets be prioritized? Choosing thick aluminum is not always the better option, but for high technical requirement items like CNC machine bases, load-bearing frames, ship decks, truck bodies, or mechanical molds, thick aluminum sheets become mandatory. It not only ensures stiffness but also reduces deformation during welding or heavy mechanical processing. However, you must also consider the trade-offs of more difficult cutting and machining, higher weight, and increased cost.

Optimize efficiency by combining aluminum grade and thickness. One tip for choosing thickness is to combine the mechanical properties of the aluminum grade and the required thickness. For example, for the same load-bearing requirement, you could use 6mm thick 6061 aluminum instead of 8mm thick 1050 aluminum because 6061 aluminum is harder and more durable. This helps reduce weight, save costs while maintaining performance. Therefore, instead of focusing solely on thickness, place it in the context of the specific aluminum grade.

Thin aluminum sheets – not just for decoration. Many people think thin aluminum sheets are only for advertising signs or aesthetics. In fact, aluminum thinner than 2mm can still be very effective in industry, if reinforced or combined with the right structure. For instance, in making vehicle cabins or lightweight partitions, thin aluminum not only helps save weight but also facilitates installation, reduces costs, and speeds up production.

Aluminum sheet thickness is not just a number – it’s a solution

Choosing aluminum sheet thickness is not a simple calculation. It is the result of fully understanding the application requirements,Working conditions and the mechanical properties of each type of aluminum. Only by combining these factors can you choose the optimal type of aluminum – saving costs, ensuring safety, and guaranteeing technical efficiency over a long period.Kenta Vietnam is the place that supplies all types of aluminum. Contact us immediately to receive a quote and direct consultation.