Knowledge, Technology

HOW TO WELD STAINLESS STEEL WITH WELDING RODS

Welding stainless steel with welding rods is a task that requires high technical skill, especially when using welding rods. Stainless steel welding rods offer many benefits, from application flexibility to reasonable cost. However, to ensure the quality of the weld, you need to master the technique, choose the right type of welding rod, and adhere to safety principles. In this article, Kenta VietNam will provide detailed instructions on how to weld stainless steel with welding rods, important notes, and small tips to achieve the highest efficiency.

How to weld stainless steel with welding rods

1. What is welding stainless steel with welding rods?

Welding stainless steel with welding rods is the process of joining stainless steel (inox) parts by heating the metal to a molten state and combining them. When using stainless steel welding rods, a protective layer (usually flux) will create a protective gas, preventing oxidation and ensuring a durable, beautiful weld.

Stainless steel welding rods are commonly used in industries such as:

- Mechanical manufacturing: Welding stainless steel parts in machine production.

- Construction: Used for projects requiring high durability and corrosion resistance.

- Household appliance manufacturing: Making sinks, stainless steel shelves, pots and pans.

2. How to choose products for the stainless steel welding process with welding rods hàn inox bằng que hàn

Criteria for choosing stainless steel welding rods

Choosing the right welding rod is the first and most important step. Factors to consider include:

- Type of stainless steel: Inox 304, 316, or 201 require different types of welding rods.

- Material thickness: Thin materials require smaller welding rods to avoid burn-through.

- Type of welding rod: Some common types of welding rods on the market:

- E308L welding rod: Suitable for inox 304 and 304L.

- E316L welding rod: Used for inox 316, with high corrosion resistance.

- E309L welding rod: Suitable for joining stainless steel materials with carbon steel.

Tips for choosing welding rods

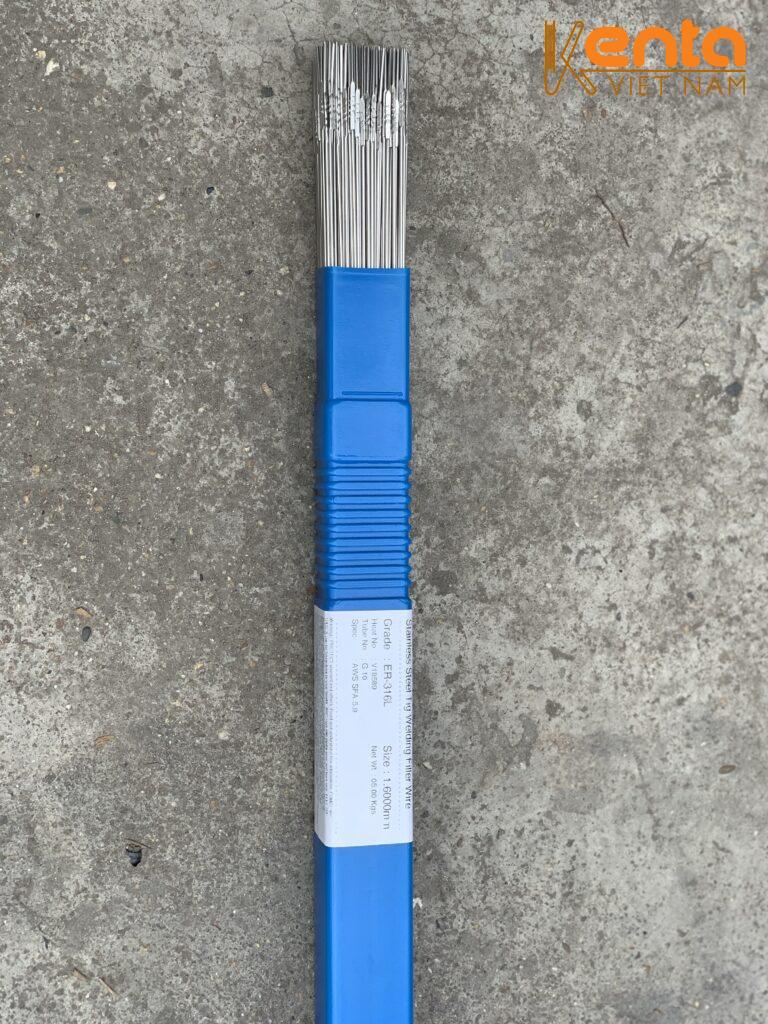

- Always check the technical specifications of the welding rod listed on the packaging.

- Use welding rods from reputable brands.

How to choose the right stainless steel welding rod

3. Stainless steel welding process with welding rods

Welding stainless steel with welding rods requires following these basic steps:

Step 1: Prepare materials and tools

- Stainless steel material: Clean the stainless steel surface before welding to remove grease and dirt.

- Welding rod: Ensure the welding rod is dry, avoid moisture absorption as it will affect the quality of the weld.

- Welding machine: Choose a welding machine capable of precise current adjustment, usually from 50-120A depending on the welding rod and stainless steel thickness.

- Protective equipment: Includes welding mask, gloves, long-sleeved shirt to protect from sparks and high temperatures.

Step 2: Set the appropriate current

- Stainless steel welding rods require a stable current to ensure good penetration.

- The ideal current is usually in the range of:

- 2.5mm welding rod: 50-80A.

- 3.2mm welding rod: 80-120A.

Step 3: Start welding

- Welding rod holding technique: Maintain an angle of about 15-30 degrees relative to the material surface for easy control.

- Welding rod movement: Perform steady movements in a "wavy" or "U-shaped" pattern to create an even and strong weld.

- Welding time: Do not prolong welding at one point to avoid burning the stainless steel.

Step 4: Inspect the weld

After completion, check the weld to see if it is even, strong, and free of porosity or cracks. If necessary, it can be ground smooth to improve aesthetics.

4. Notes when welding stainless steel with welding rods

- Ensure a well-ventilated welding environment to avoid inhaling harmful welding fumes.

- Always wear safety glasses and heat-resistant gloves.

- Stainless steel is easily deformed by heat. Therefore, it is necessary to control the welding temperature and cool it quickly after completion.

- Stainless steel welding rods are prone to moisture absorption, so store them in a dry place and use them immediately after removing them from the packaging.

- Always test on a sample material before proceeding with the main product.

- Increase welding speed for short welds to reduce heat accumulation.

- Use additional shielding gas (if available) to improve weld quality.

Notes when welding stainless steel with welding rods.

5. Some common errors when welding stainless steel with welding rods

- Uneven weld: Due to unstable welding rod movement, practice the rod holding technique.

- Porosity: May be due to damp welding rods, check and dry the rods before use.

- Material deformation: Lower the current or use spot welding technique to reduce temperature.

Conclusion

Welding stainless steel with welding rods is not a difficult technique but requires patience, skill, and thorough preparation.Choosing the right type of welding rod, adjusting the current appropriately, and adhering to safety principles are crucial factors that help you achieve beautiful, strong, and durable welds.

We hope this article has provided you with useful information on how to weld stainless steel with welding rods. Learn more at Kenta VietNam for additional information on welding materials!