Knowledge, Technology

Characteristics and Applications of Aluminum Sheets

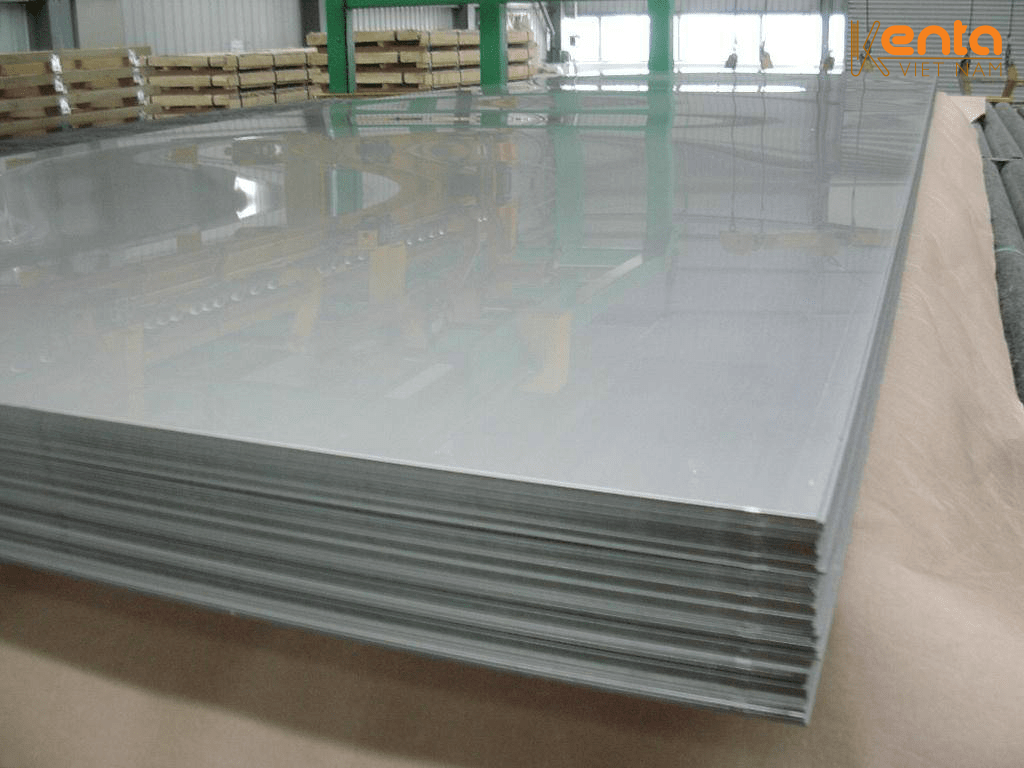

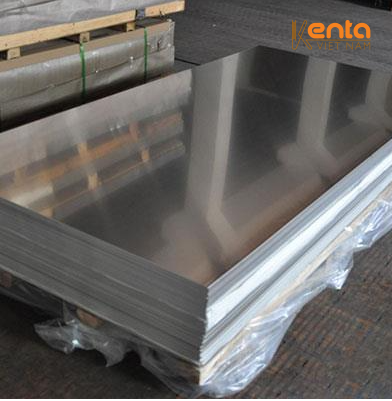

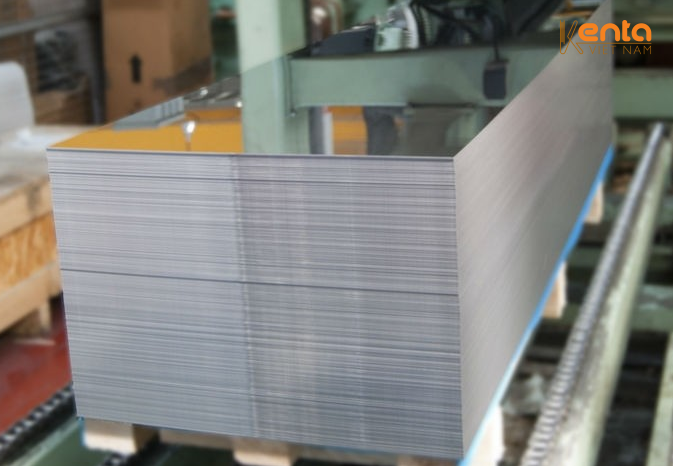

As manufacturing technology advances, the requirements for materials are also increasing. Among them, aluminum sheets have emerged as an indispensable solution in many fields due to their versatility and stable durability. This is not only a lightweight metal that is easy to process but also meets many strict standards in both technical and aesthetic aspects. So, what makes aluminum sheets uniquely attractive, and how are their characteristics and applications used in practice?

What is special about aluminum sheets?

Unlike many other metals, aluminum sheets have an important advantage of being lightweight while still ensuring the necessary hardness and durability. Thanks to its low density, aluminum helps reduce the overall weight of structures while maintaining good load-bearing performance. This is especially meaningful in industries such as transportation, aviation, and construction, where every kilogram saved brings clear economic value.

In addition to being light, aluminum is also easy to shape, bend, or cut without degrading the material quality. Its ductility and stable tensile strength help mechanical workshops save time in machining while improving the precision of finished products. Many businesses prioritize aluminum sheets because of their good surface treatment capabilities, allowing easy painting or anodizing, resulting in products that are both sturdy and visually appealing.

Another significant advantage lies in its natural oxidation resistance. When exposed to air, aluminum forms a thin oxide layer that acts as a "shield" protecting the surface from environmental effects. Thanks to this mechanism, aluminum sheet components maintain a long-lasting glossy appearance and degrade less, even when used outdoors or in humid environments.

Where are aluminum sheets used in practice?

With all these outstanding features, aluminum sheets are present everywhere in daily life. From industrial equipment, machine frames, to aluminum doors, building facades, or household furniture – traces of this material can be found everywhere. In mechanical manufacturing, aluminum sheets are an ideal choice for parts that require high durability without increasing equipment weight. Their stable load-bearing and heat resistance allow aluminum to meet the stringent requirements of industrial machinery.

The transportation industry, especially aviation and automobiles, also fully exploits the advantages of aluminum sheets. Lightweight means fuel savings, increased operating efficiency, and reduced long-term operating costs. This is why more and more manufacturers prefer aluminum over traditional steel.

Not limited to heavy industry, aluminum sheets are also popular in modern construction projects. High-rise buildings, commercial centers, or houses use aluminum for facades, aluminum-framed glass doors, or sun shading systems. Aluminum not only provides high aesthetics but is also easy to maintain and has a long lifespan, aligning with the trend of green and sustainable architecture.

Conclusion

It can be seen that aluminum sheets are not simply an ordinary metal material. With the characteristics of being lightweight, durable, easy to process, and corrosion-resistant, aluminum is becoming the preferred trend in many modern industries. From mechanical manufacturing, transportation to construction and residential life, aluminum sheets increasingly prove their value and wide-ranging application potential.

If you are looking for a high-quality aluminum sheet supplier with a diverse range of aluminum grades and full COCQ certifications, contact Kenta VietNam – a trusted partner of hundreds of mechanical, construction, and manufacturing enterprises nationwide. We are committed to providing genuine products, dedicated consultation, and reasonable prices for every project!