Knowledge, Technology

What is the standard thickness of aluminum sheets?

In the fields of mechanics, construction, or industrial production, aluminum sheets are a familiar material. Whether you are a newcomer or have been in the profession for a long time, you may have wondered: What is the standard thickness of aluminum sheets? This seemingly simple question can lead to wasted costs or even affect the durability of the product if misunderstood or incorrectly chosen.

Understanding the standard thickness of aluminum sheets not only helps in selecting the appropriate material but also ensures safety, optimizes work performance, and prolongs the lifespan of equipment.

Why is thickness an important factor when choosing aluminum sheets?

Each aluminum sheet has two important technical specifications: size and thickness. Among these, thickness plays a decisive role when it comes to hardness, load-bearing capacity, bending ability, and overall weight.

For example, if you use aluminum that is too thin for a vehicle floor or support bracket, the sheet may easily sag, warp, or crack after some time of use. Conversely, if you use a sheet that is too thick for details that only require light decoration, it not only costs more but also becomes heavy and difficult to process.

That is why it is essential to understand the standard thickness – to choose "the right type for the right job" and save budget.

What are the common thicknesses of aluminum sheets?

In practice, aluminum sheets are produced in many different thicknesses, depending on the usage requirements and rolling technology. However, the most common thicknesses in the current market range from 0.5mm to approximately 75mm.

If you are looking for aluminum to make advertising boards or lightweight wall panels, sellers will recommend thin aluminum sheets ranging from 0.5mm to 1mm. Generally, these sheets are lightweight, easy to bend, and convenient to cut – very suitable for aesthetic purposes that do not require load-bearing.

For aluminum used in machinery production, electrical cabinets, and equipment casings, an average thickness of about 2mm to 6mm would be a reasonable choice. This type is stiff enough to ensure stability while still not being too heavy to complicate processing.

In fields such as mold making, large structure fabrication, ship flooring, or high-load equipment, aluminum sheets with a thickness ranging from 10mm to 75mm are used, and in some cases, even up to 100mm depending on technical requirements.

Is a greater thickness always better?

The answer is no. Thickness does not determine everything. Choosing the right thickness should be based on two factors: the intended use and the aluminum grade. Some aluminum types, although not thick, can still have sufficient stiffness if they belong to high-grade alloys like 6061 or 7075. Conversely, pure aluminum like 1050 despite being thicker, is softer and more prone to deformation.

Therefore, selecting aluminum requires considering both the aluminum grade and thickness. Don't just look at the millimeter number – understand the properties to avoid mistakes in material selection.

What is the standard thickness of aluminum sheets in practice?

When speaking of "standard," it is generally understood to mean the most commonly used type. In the aluminum industry, thicknesses from 1mm to 6mm are considered common standards. This thickness is suitable for most needs, from residential to light industrial applications, easy to process, and reasonably priced.

For example, a typical electrical cabinet will use aluminum with a thickness of 2mm to 3mm. A machine body or CNC workbench will be chosen from 5mm and above. If you need to build a truck bed or load-bearing floor, you may have to use 8mm – 12mm or more.

There is no universal number for all purposes, but manufacturers often recommend standard "commercial" thicknesses for easier stocking, cutting, and pricing. You can also easily find these thicknesses at most reputable aluminum sheet warehouses like Kenta Vietnam.

Kenta Vietnam – Providing aluminum sheets with the correct standard thickness

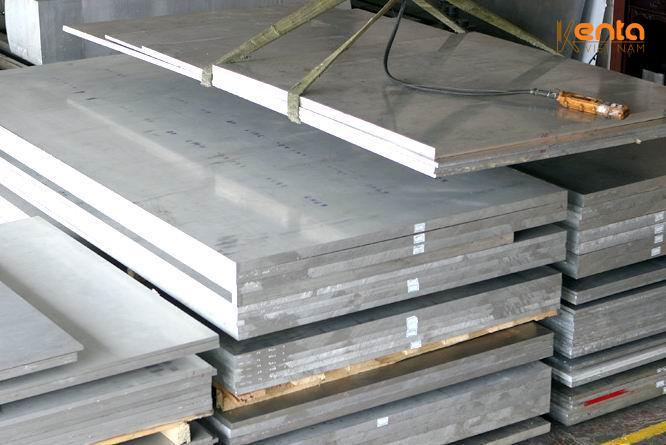

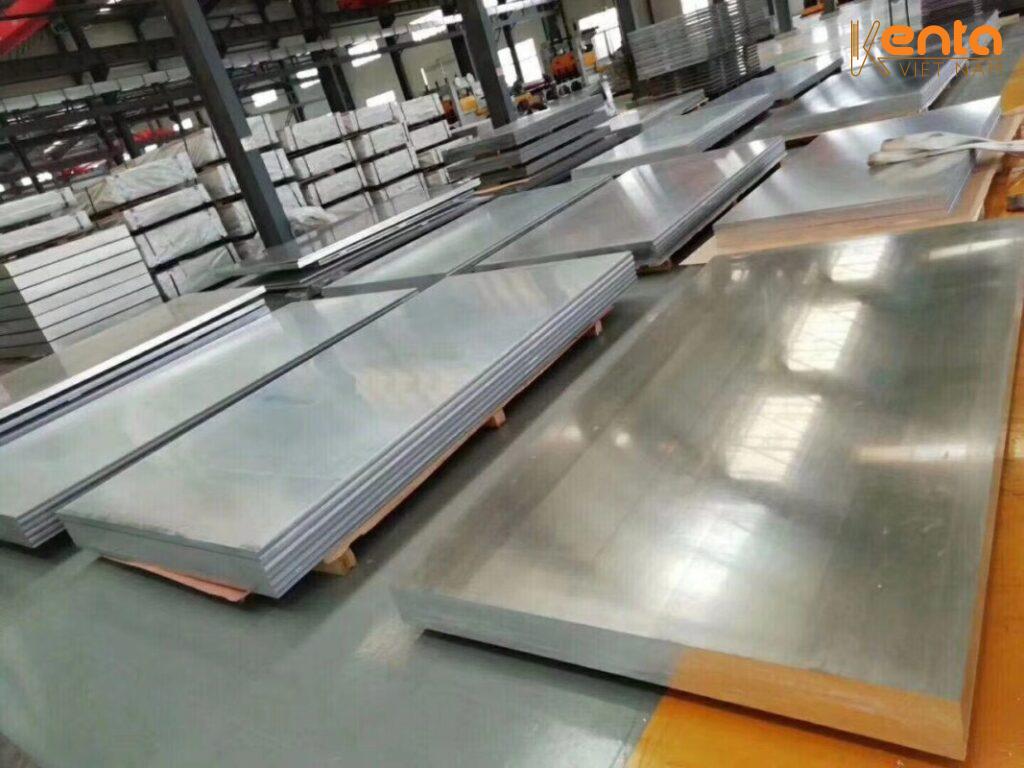

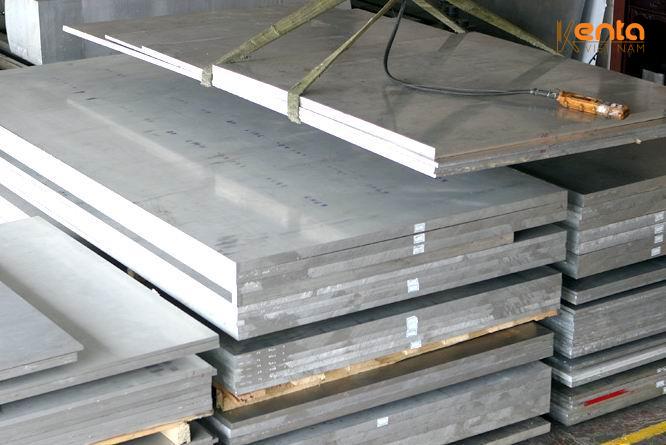

At Kenta VietNam, with a full range of thicknesses according to standards from 0.5mm to 75mm. You can find popular aluminum grades such as 1050, 5052, 6061, 7075 with precise thickness down to the millimeter.

We are committed to:

- Advising on the appropriate thickness for each intended use.

- Cutting aluminum as required, to the correct size and thickness.

- Providing clear CO – CQ certificates to ensure origin.

- Offering on-site technical support if needed, especially for large orders.

The most important thing is that you understand what you need – from there, choose the right material, the right thickness, and the right value. And if you still have concerns, let Understanding this, Kenta VietNam accompany you in every step of the selection process.