Knowledge, Technology

What shielding gas is needed for aluminum welding?

In aluminum welding, choosing the right shielding gas is a crucial factor for creating beautiful, strong welds and minimizing technical defects. So, what shielding gas is needed for aluminum welding? This article will help you understand the role of shielding gas, common types of gases, their advantages and disadvantages, and how to choose the appropriate one for both beginners and experienced welders.

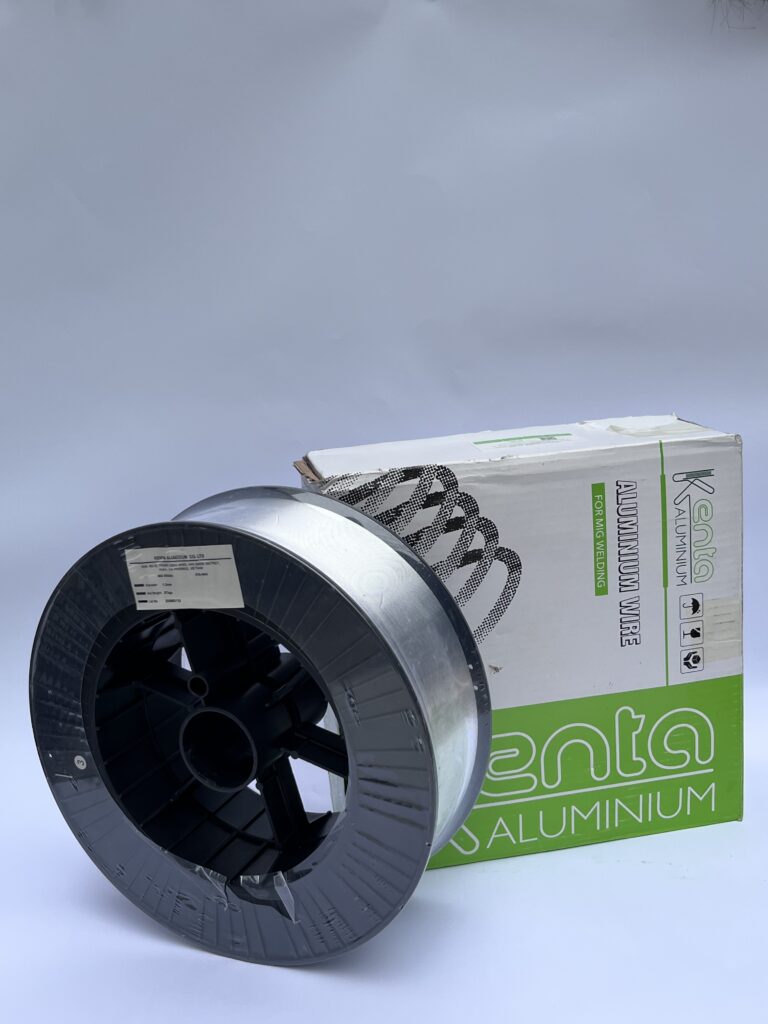

Are you looking for high-quality aluminum welding materials? Kenta VietNam currently distributes a wide range of welding gases, aluminum welding wires, and accompanying accessories – ensuring technical standards, competitive prices, and on-site technical support.

Why is shielding gas needed for aluminum welding?

When welding aluminum, without shielding gas, the molten metal is prone to oxidation when exposed to air. As a result, the weld is susceptible to porosity, weakness, or even cracking after a period of use.

Shielding gas helps to:

- Prevent oxidation

- Stabilize the welding arc

- Reduce smoke and spatter

- Increase the aesthetic appeal and durability of the weld

Common types of shielding gases used in aluminum welding today

1. Pure Argon gas (100%)

- Is the most common and easiest gas to use

- Inert gas, does not react with molten metal

- Stabilizes the arc, suitable for both TIG & MIG welding

Kenta suggested products:

- Argon gas 99.999% – available in standard 10L, 14L, 40L cylinders

- Safra 4043, 5356 aluminum welding wire – diameters from 1.2mm to 2.4mm, specifically for TIG and MIG

2. Argon + Helium mixture

- Provides higher heat input, suitable for welding thick materials

- Strong arc, deep penetration

- Common in industrial aluminum welding, large structures

Kenta suggested products:

- Pre-mixed Argon + Helium 75/25 or 90/10, with full certification

- Large spools of aluminum welding wire 7kg/15kg, suitable for high-power welding machines

3. Argon + CO₂ gas (not recommended)

- Should not be used for aluminum welding because CO₂ causes porosity and corrosion

- Often confused with steel welding gas

Shielding gas suitable for each welding method

Aluminum TIG welding (GTAW)

Use: Pure Argon

Advantages: Easy arc control, less smoke, bright and beautiful welds

Accompanying materials:

- Aluminum welding wire 4043– made in Italy

- Argon gas type 5.0 – compact and convenient 10L or 14L cylinder

Aluminum MIG welding (GMAW)

Use: Pure Argon or Argon + Helium

Advantages: Fast welding speed, suitable for large-scale production

Accompanying materials:

- Aluminum welding wire spool 5356 – Ø1.2mm, Ø1.6mm

- Argon gas or Argon + Helium mixture in 40L cylinders – ensures stable arc

Notes when using shielding gas

Appropriate gas flow rate:

- Depends on material thickness and torch tip, usually 10–20 liters/minute

- Recommendation: use Kenta pressure regulator + flow meter – accurate, easy to adjust

Check the gas delivery system:

- Even small leaks can cause protection to be ineffective

- Kenta provides a full range of valves, hoses, threaded connectors, easy to replace

Clean the material surface:

- Use Kenta stainless steel brush or specialized cleaning solution to remove oxidation layers and grease

Conclusion

For most aluminum welding jobs:

Pure Argon is the optimal choice. For thick aluminum or high-requirement products: Argon + Helium is a solution to enhance efficiency

Are you looking to buy genuine, good-priced aluminum welding materials?

Kenta VietNam specializes in providing:

- SAFRA (Italy) aluminum welding wire – TIG, MIG, large spools & cut lengths

- Argon – Helium gas – industrial standard shielding gas mixtures

- Synchronized welding accessories: welding torches, gas hoses, valves, flow meters…