Knowledge, Technology

What type of tungsten is needed for aluminum TIG welding?

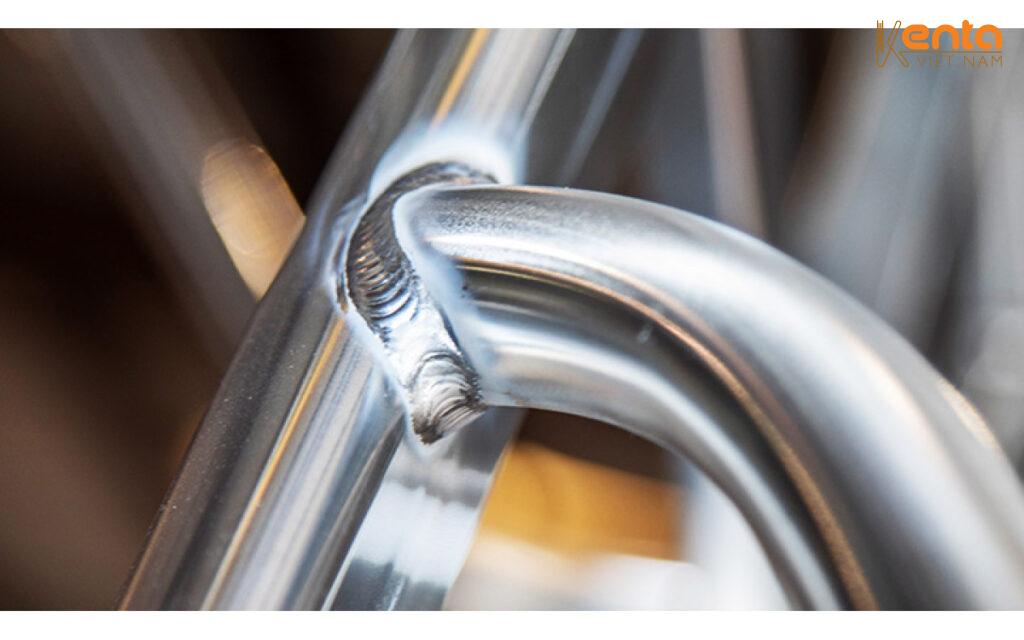

When it comes to aluminum TIG welding, many people immediately think of the shiny welds and high aesthetics that this method brings. But to achieve that result, it's not only about having a good welding machine or skilled technique but also choosing the right type of welding electrode. So, what type of tungsten is needed for aluminum TIG welding? This question seems simple but is a decisive factor for the weld quality.

Why is choosing tungsten important in aluminum TIG welding?

Tungsten, also known as a tungsten electrode, is the main component that creates the arc during the TIG welding process. Although it does not directly melt or add material to the weld, it plays a role in controlling the heat source – a factor that directly affects the melting capability of aluminum and the final weld quality.

When welding aluminum, if you use the wrong type of tungsten, the arc will be unstable, prone to flickering, causing shallow weld penetration, gas porosity, or burn-through at the edges. Moreover, using the wrong electrode reduces tungsten lifespan, increases material costs, and disrupts work.

Characteristics of aluminum TIG welding and specific requirements for tungsten

Unlike welding steel or stainless steel, aluminum TIG welding requires AC mode (alternating current). Aluminum has a firmly adhered oxide layer on its surface – a layer that melts at a much higher temperature than the base material beneath. Therefore, AC mode helps both remove the oxide layer and melt the aluminum simultaneously, producing clean and even welds.

This characteristic also causes the requirement for the tungsten type in aluminum TIG welding to differ. You need an electrode capable of creating a stable arc in AC mode, resistant to tip wear, and not easily melting at the electrode tip during continuous current fluctuations.

So, what type of tungsten is needed for aluminum TIG welding?

To accurately answer “what type of tungsten is needed for aluminum TIG welding?”, we need to consider the working conditions and characteristics of each tungsten type.

In the environment of TIG aluminum welding with AC, the most commonly used tungsten types were green (pure tungsten – WP) and red (thoriated – WT20) previously. However, nowadays, many professionals and factories switch to using white (zirconiated – WZr) or blue (lanthanated – WL20) tungsten due to their superior advantages.

WZr (white) electrodes are often preferred in aluminum TIG welding because of their high heat resistance, ability to maintain a stable rounded tip in AC current, helping achieve an even and easily controllable arc. They also corrode less compared to pure tungsten.

Meanwhile, WL20 (blue) is a versatile choice for both AC and DC. Although not optimized 100% for aluminum like WZr, WL20 offers high durability and a sharp arc, suitable for those who need a multipurpose option when working with both stainless steel and aluminum.

Notes when using tungsten for aluminum TIG welding

Besides selecting the correct tungsten type, you also need to pay attention to the size and tip shape. For aluminum TIG welding in AC mode, the electrode tip should be ground round or shaped like a hemisphere – not sharpened as in steel welding with DC. A tip that’s too sharp can crack during the current polarity reversal, damaging the weld and posing a hazard to the operator.

The tungsten diameter should also be compatible with the current you use. For thin aluminum sheets (under 3mm), electrodes ranging from 1.6mm to 2.4mm are suitable. If welding larger structures, use 3.2mm electrodes to better withstand heat while maintaining a stable arc.

Common mistakes in choosing tungsten for aluminum welding

One common mistake is reusing old electrodes that were used for steel or stainless steel welding to weld aluminum. While this may seem economical, it causes arc instability, easily leading to misfiring and affecting the entire weld.

Another mistake is using a sharp tip for AC welding. This grinding style is common for DC but unsuitable for aluminum, causing quick tungsten wear, arc interference, and surface quality degradation.

Recommended tungsten electrode selection from Kenta Vietnam

At Kenta VietNamprovides a wide range of high-quality tungsten types used for TIG welding,Especially optimized for aluminum such as Zirconiated (WZr – white tip) and Lanthanated (WL20 – blue tip). The needles are officially imported, with diameters ranging from 1.6mm to 3.2mm, standard packaging, and always available in stock.

In addition, Kenta's technical team is ready to advise you on selecting the right needle type based on the machine model, material, thickness, and current used, helping to optimize efficiency and save long-term costs for your workshop or personal use.