Knowledge, Technology

How to limit porosity when welding aluminum?

Porosity is always a nightmare for welders when working with aluminum sheets. The weld looks good on the outside, but inside there are tiny gas holes – not only affecting durability but also causing aesthetic damage and reducing the overall quality of the product. So, how to limit porosity when welding aluminum? This article will go with you from the cause to the solution, and also suggest choosing suitable materials to minimize errors from the beginning.

To weld aluminum with less porosity, you must start with the material.

One thing that many people don't pay attention to is that the quality of the input material directly affects the gas generation in the weld. If the aluminum sheet does not have high purity, contains many impurities, has a thick oxide layer, or an uneven surface, no matter how carefully you adjust the machine, the weld still has a risk of defects.

At Kenta VietNamAt Kenta VietNam, we advise customers to choose specialized aluminum sheets for aluminum welding, such as aluminum 5052 or aluminum 6061,available in stock in various thicknesses, large sizes (1200x2400mm, 1500x3000mm...), with full COCQ certificates.

Especially, aluminum 5052 is highly rated for TIG or MIG welding – because it has a suitable alloy composition, fewer impurities, a stable surface oxide layer, is easy to control during welding, and the weld has less porosity. For structures requiring higher mechanical properties, aluminum 6061 is also a stable choice, if accompanied by the correct welding wire and appropriate technique.

Surface cleaning is a mandatory step before welding aluminum.

The aluminum surface may seem clean, but in reality, it contains many oxide layers and moisture that have accumulated over time. This is the "gas source" that causes porosity if not removed before welding. Therefore, proper cleaning is mandatory if you want to control porosity.

You can use a soft stainless steel brush to remove the oxide layer, or better yet, use a specialized etching solution for aluminum – which helps remove oxide without scratching the surface. After treatment, it must be completely wiped dry with a clean cloth, and aluminum should not be touched with bare hands (because sweat also contains moisture and impurities).

At Kenta, when delivering aluminum to customers for processing, we always recommend using new aluminum sheets – stored dry – instead of long-stored aluminum, to minimize risks during welding. Sometimes, a small detail like a thin oxide layer can cause an entire batch of products to have weld defects.

Choose the right aluminum welding wire and shielding gas.

Many people only pay attention to the welding machine and ignore the wire and gas – while these are the factors that help "control" oxygen and hydrogen throughout the welding process.

For aluminum 5052, the most common aluminum welding wire is ER 5356 – for strong welds, good penetration, and effective reduction of porosity. For aluminum 6061, ER 4043 can be used if a smoother weld surface is desired, making it easier to process after welding. Aluminum welding wire must always be stored in a moisture-proof bag, not exposed to air for too long.

Regarding shielding gas, pure Argon (99.99%) is the top choice to limit porosity. If conditions permit, you can use an Argon-Helium mixture to improve heat transfer and deeper penetration, especially when welding thick aluminum sheets.

How to adjust welding techniques and machine parameters correctly?

A beautiful weld with less porosity cannot be achieved without skill and technical understanding. The welder needs to choose the correct current, voltage, wire feed speed, and travel speed. If welding too fast, the gas will be trapped before it can escape. If too slow, the weld will be heated for too long and easily absorb moisture from the air.

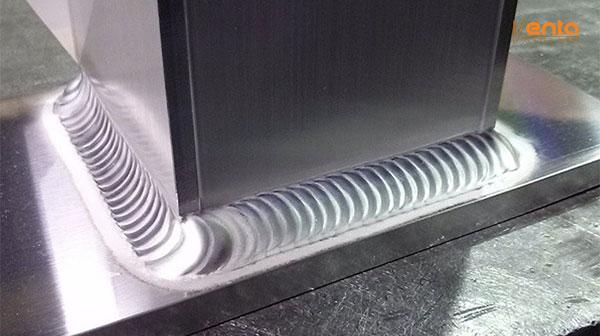

For TIG welding, AC current with balanced polarity adjustment should be used, allowing the oxide layer to be broken and the weld area to be heated evenly. If it's MIG, the wire speed must be stable, combined with a steady travel speed to avoid localized hot spots.

When welding thin aluminum sheets (under 3mm), technicians need to be extremely careful because the weld is very susceptible to burn-through or gas bubbling if moving too fast or allowing the arc to fluctuate too much.

How to detect porosity and treat it after welding.

Gas porosity is not always visible to the naked eye, especially when it is located inside the weld. For high-requirement products, you can use ultrasonic testing or X-ray imaging to detect hidden gas porosity. In mass production, gas porosity often recurs cyclically, so it can be prevented from its root cause.

If gas porosity is detected, the weld needs to be ground down and re-welded from scratch. It should not be "patched up" by adding metal on top – because this leaves the defect inside, making it prone to cracking and breaking during long-term use.

At Kenta VietNam, we support customers from aluminum selection – welding wire consultation – to connecting with qualified processing units. This helps users avoid errors in the actual process, especially for export products or structures with high technical requirements.

Preventing porosity when welding aluminum is not difficult if done correctly from the start.

Porosity in aluminum welding is a common defect but can be completely prevented. Cleaning the material, choosing the right welding wire and gas, setting appropriate parameters, and understanding material properties will help you create clean, strong, and aesthetically pleasing welds.

If you are looking for high-quality aluminum sheets for MIG or TIG welding, consider the 5052 – 6061 aluminum series available at Kenta VietNam. With a diverse inventory, support for custom cutting, and dedicated technical consultation, Kenta is not only a material supplier but also a reliable companion in every mechanical and manufacturing project.