Knowledge, Technology

How are 5052 and 6061 aluminum sheets different?

When choosing aluminum sheets for mechanical, architectural, or industrial projects, distinguishing between 5052 and 6061 aluminum sheets is essential. Both are common aluminum alloys, sharing many similarities but also possessing important differences that directly affect their performance, durability, and project cost.

In this article, Kenta Vietnam will help you understand how 5052 and 6061 aluminum sheets differ, thereby enabling you to make the most suitable choice for all your needs.

What are 5052 and 6061 aluminum sheets? Basic definitions of these two types of aluminum.

Before delving into a detailed comparison, let's explore the definitions and general characteristics of each type:

Aluminum Sheet 5052 is a superior corrosion-resistant alloy belonging to the aluminum-magnesium alloy series (5xxx series). This type of aluminum does not undergo heat treatment to increase hardness, but it stands out for its excellent corrosion resistance and high strength under non-heat-treated conditions. Therefore, 5052 is a top choice for applications in marine environments, where there is high humidity and corrosive chemicals.

Conversely, 6061 aluminum sheet is a high-strength structural alloy belonging to the aluminum-magnesium-silicon alloy series (6xxx series). A prominent feature of 6061 is its ability to be heat-treated to increase hardness and yield strength, typically to the T6 temper. This alloy possesses good mechanical properties, is easy to weld, and easy to machine, making it an ideal material for applications requiring high structural strength in machine manufacturing, automobiles, molds, and construction.

Detailed comparison of how 5052 and 6061 aluminum sheets differ.

To make an accurate choice, a deep analysis of the differences between 5052 and 6061 aluminum sheets is crucial:

1. Alloy composition

The most fundamental difference lies in the alloy composition. 5052 aluminum primarily contains aluminum (Al), magnesium (Mg, about 2.5%), and a small amount of chromium (Cr). Importantly, 5052 does not contain silicon as a main component, thus it cannot be heat-treated for strengthening. In contrast, 6061 aluminum includes aluminum, magnesium (about 1.0%), and silicon (about 0.6%). The presence of silicon is the factor that allows 6061 to be heat-treated, enabling it to achieve much higher hardness and strength.

2. Corrosion resistance

This is a major difference between the two types. 5052 aluminum possesses excellent corrosion resistance, especially superior in saltwater marine environments and mild chemicals. This makes it an ideal material for applications such as shipbuilding, chemical tank manufacturing, or refrigerated containers. Conversely, 6061 aluminum has fair corrosion resistance, sufficient for normal environmental conditions, but it is not the optimal choice for seawater or strong corrosive chemical environments.

3. Mechanical strength

In terms of mechanical strength, 6061 aluminum has significantly superior tensile strength and hardness compared to 5052, especially when in the T6 heat-treated condition. If your project requires a material that can withstand large forces, used for machine frames or load-bearing technical parts, 6061 is definitely a more reasonable choice. Although not as hard, 5052 aluminum still provides sufficient ductility and strength for applications requiring bending, stamping, or stretching without cracking.

4. Machinability and weldability

Both types of aluminum can be machined, but with their own specific characteristics. 5052 aluminum is known for its ease of bending, stamping, and cutting. The weldability of 5052 is also very good; it can be welded using MIG and TIG methods without worrying about cracking. Meanwhile, 6061 aluminum can be machined by various methods, including CNC, but more attention is needed during welding as there is a risk of cracking at high temperatures, and it often requires post-weld heat treatment to restore strength.

5. Surface treatment capability (Anodizing)

Both 5052 and 6061 aluminum can be anodized to increase color fastness, wear resistance, and create an aesthetic appearance. However, it is worth noting that 6061 often yields a more uniform and brighter surface after anodizing compared to 5052, which is a factor to consider if surface aesthetics are a top priority.

6. Cost

In terms of cost,5052 aluminum is usually slightly more affordable than 6061. The reason is that 5052 is not heat-treated and has a simpler manufacturing process. In contrast, 6061 aluminum is more expensive because it belongs to a higher-grade alloy series with superior mechanical properties and a more complex production process (including heat treatment).

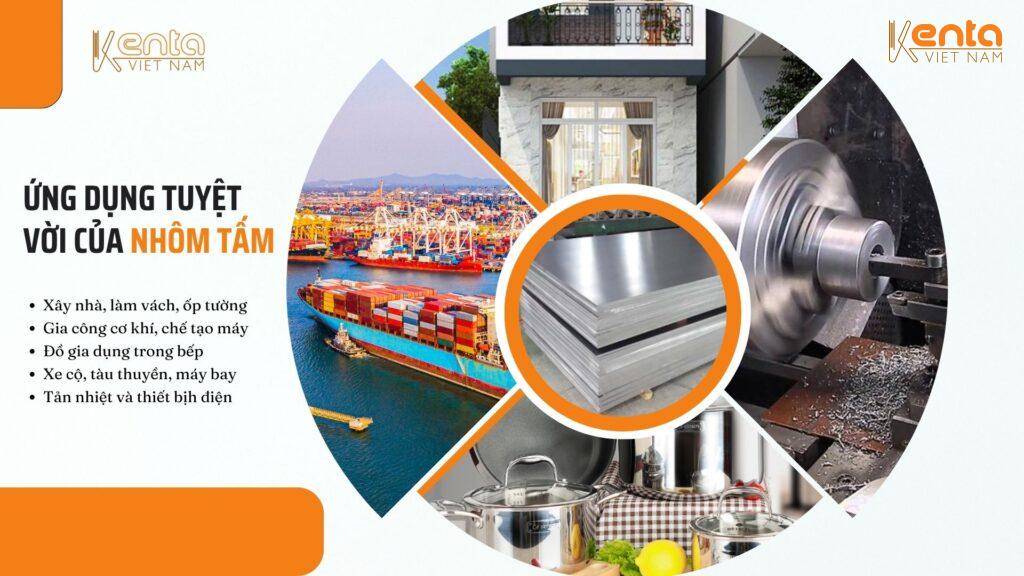

What are the practical applications of 5052 and 6061 aluminum sheets?

Based on their characteristic differences, these two types of aluminum sheets are applied in separate fields:

Aluminum Sheet 5052: With good corrosion resistance and ductility, 5052 is often used for truck bodies, containers, refrigerated boxes, chemical storage tanks, shipbuilding and marine equipment, as well as outdoor partitions and signs where weather resistance is required.

6061 aluminum sheet: Thanks to its superior strength and heat treatment capability, 6061 is the top choice for vehicle frames, automotive components, bicycles, mechanical molds, sports equipment, LED lights, and structures such as stairs and aluminum structures in construction.

So, should you choose 5052 or 6061 aluminum sheet?

The choice of the appropriate aluminum sheet depends entirely on the specific application and technical requirements of the project.

Choose Aluminum 5052: if you need a material that is easy to bend, has excellent corrosion resistance (especially in marine environments), and is affordable.

Choose Aluminum 6061: if your project requires high hardness and strength, precise machining, and you are willing to pay a higher cost to achieve optimal mechanical performance.

Kenta Vietnam – Reputable Aluminum Sheet Supplier

Kenta Vietnam is proud to be a unit specializing in supplying high-quality 5052 and 6061 aluminum sheets , with full Certificates of Origin – Quality (CO-CQ) and genuine imported goods from the EU, Korea, and China. We offer a diverse range of thicknesses from 0.5mm to 100mm, support CNC cutting on demand, and provide fast nationwide delivery.

Conclusion

Aluminum sheet 5052 and 6061 are both excellent materials, but they will maximize their utility when used for the right purpose. We hope this article has helped you understand the differences between these two types to make the correct choice for your project.

Do you need advice on the right type of aluminum? Contact Kenta VietNam – an aluminum material expert with over 10 years of experience in the industry – for the most dedicated support.