Knowledge, Technology

5052 vs 6061 Aluminum Sheet: Which is Best for Structural Engineering? Kenta Vietnam

Detailed comparison of 5052 and 6061 aluminum sheets regarding properties, applications, durability, processing, and cost. Find out which aluminum sheets aluminum sheet is best suited for structural engineering manufacturing. Contact Kenta VietNam for optimal solutions.

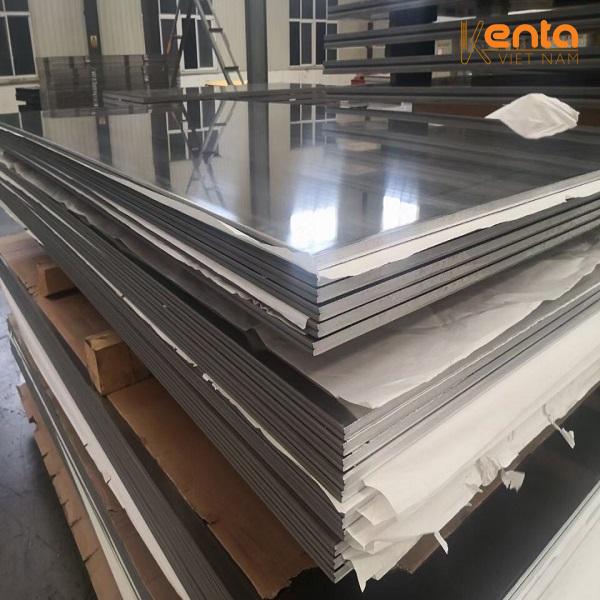

Comparing 5052 and 6061 Aluminum Sheets: Which Should You Choose for Structural Engineering Manufacturing?

In the structural mechanical manufacturing industry, selecting the appropriate materials is a key factor that determines the durability, performance, and cost of the final product. Among the common types of aluminum alloys, 5052 aluminum sheet and 6061 aluminum sheet are usually the two most considered candidates. Each type has its own distinct characteristics, suitable for different technical requirements. This article will delve into comparing the two types. aluminum sheets This helps you make informed decisions for your project while introducing the benefits of choosing materials from. Kenta VietNam.

Overview of 5052 and 6061 Aluminum Sheets

To make an accurate choice, we first need to understand the basic characteristics and applications of each type of aluminum sheets.

Basic Characteristics of 5052 Aluminum Sheet

Aluminum Sheet 5052 belongs to the aluminum-magnesium alloy group, notable for its excellent corrosion resistance, especially in marine and chemical environments. It is a non-heat-treatable alloy with medium to high tensile strength. Good ductility and superior weldability are major advantages of aluminum 5052making it easy to process and bend without cracking.

Basic Characteristics of 6061 Aluminum Sheet

Aluminum Sheet 6061 is an aluminum-magnesium-silicon alloy, known for its ability to be heat-treated to enhance strength. It has high tensile strength, good corrosion resistance (though less than 5052 in saltwater environments), and is particularly easy to machine (milling, turning, drilling). Aluminum 6061: also has very good weldability and is one of the most versatile alloys.

Practical Applications of the Two Aluminum Types

- Aluminum Sheet 5052Often used in applications requiring high corrosion resistance and good ductility such as boat hulls, chemical tanks, oil and gas pipelines, marine equipment, electronic enclosures, and traffic signs.

- Aluminum Sheet 6061Popular in structures requiring high strength and good machinability such as bicycle frames, automotive components, small aircraft structures, bridges, machine parts, molds, and precision components.

Comparison Criteria Between 5052 and 6061 Aluminum Sheets

When choosing between aluminum 5052 and aluminum 6061, for structural engineering manufacturing, the following criteria are extremely important.

Mechanical Properties

- Tensile strength and hardness:: Aluminum 6061: (especially after heat treatment like T6) has significantly higher tensile strength and hardness compared to aluminum 5052This makes 6061 6061 more suitable for applications under heavy loads and requiring high rigidity.

- Ductility: Aluminum 5052: has better ductility and bendability, making it an ideal choice for applications requiring complex shaping or forming without fear of cracking.

Corrosion Resistance Characteristics

- General corrosion resistance: Cả hai loại đều có khả năng chống ăn mòn tốt. Tuy nhiên, aluminum 5052 vượt trội hơn trong môi trường biển mặn, nước lợ và các môi trường hóa chất mạnh do hàm lượng magiê cao.

- Stress corrosion: Aluminum 6061: : Both types have good corrosion resistance. However, aluminum 5052 excels in saltwater, brackish water, and strong chemical environments due to its high magnesium content.

Ease of Processing and Welding

- Machining (milling, turning, drilling):: Aluminum 6061: is generally easier to machine than aluminum 5052 due to its grain structure and better chip formation.

- Weldability: Both have very good weldability using common welding methods such as TIG and MIG. However, aluminum 5052 5052 aluminum is generally considered slightly easier to weld and less prone to cracking after welding. Aluminum 6061: may require re-heat treatment after welding to restore maximum strength.

Cost and Economic Efficiency

Generally, the cost of aluminum 5052 and aluminum 6061, is quite competitive and can fluctuate depending on the supplier, thickness, and quantity. However, when considering economic efficiency, you need to consider:

- Purpose of useIf high durability and heavy load-bearing capacity are required, 6061 may be a more economical choice, even if the price is slightly higher.

- Working environment:If the environment is harsh and highly corrosive, 5052 will provide a longer lifespan, reducing maintenance costs.

- Processing cost:Although 6061 is easier to process, 5052 is easier to bend and shape, which can save costs for complex parts.

Benefits of Choosing Aluminum Sheets from Kenta VietNam

To ensure optimal quality and efficiency for structural mechanical projects, choosing a reputable supplier is a key factor. Kenta VietNam is a reliable partner in this field.

Guaranteed Product Quality

Kenta VietNam is committed to providing 5052 and 6061 aluminum sheets that meet international standards, with clear origins and full quality certifications. This ensures that the product you receive has the correct mechanical and chemical properties as desired, avoiding the risk of material quality affecting the structure.

Excellent Customer Support Service

Kenta VietNam's team Kenta VietNam of experts is always ready to provide in-depth consultation, helping you analyze the technical requirements of your project and choose the most suitable type of aluminum sheets between 5052 và 6061. Dedicated technical support before and after sales helps resolve all questions and issues that arise.

Competitive Price

With the advantage of product sources and optimized processes, Kenta VietNam provides 5052 and 6061 aluminum sheets at competitive prices, helping you optimize investment costs while ensuring product quality.

Conclusion

The choice between 5052 and 6061 aluminum sheets for structural mechanical manufacturing depends on the specific requirements of each project. If the highest strength and hardness are needed for heavy-load-bearing components and heat treatment capability, aluminum 6061, is the preferred choice. Conversely, if the project requires excellent corrosion resistance (especially in marine environments) and ductility for easy bending,, aluminum 5052 will be the optimal solution.

Whichever type you choose, partnering with a reputable supplier like Kenta VietNam will ensure you receive high-quality products and professional support services, contributing to the success of your project.