Knowledge, Technology

Can aluminum sheets be laser cut?

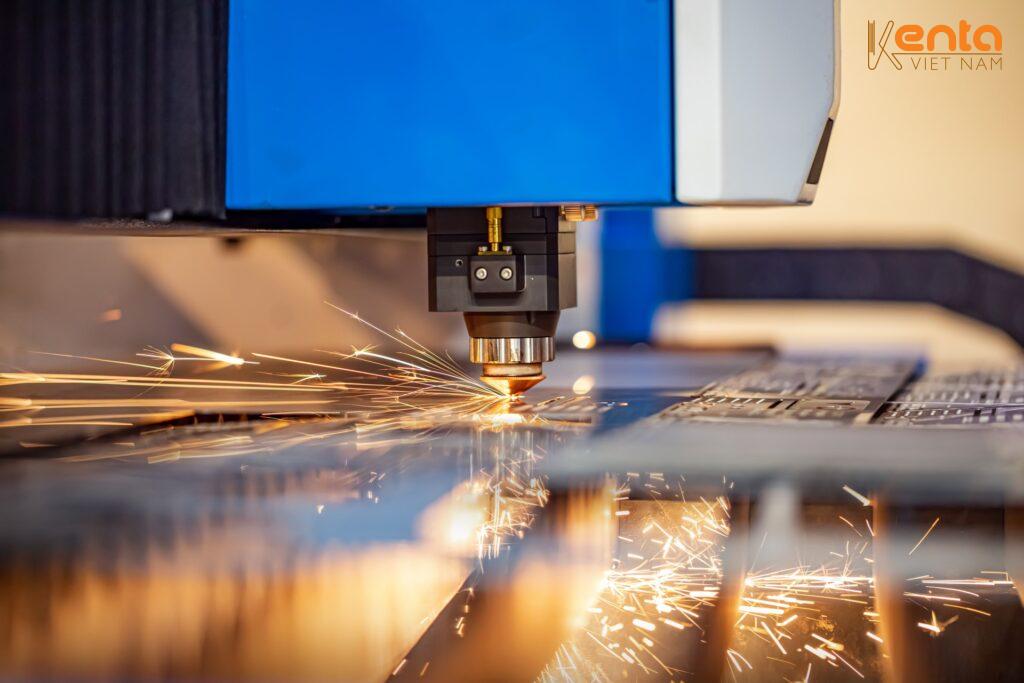

Laser cutting is one of the most popular metal processing methods today due to its high precision, fast speed, and superior flexibility. However, when it comes to aluminum sheets, many people still wonder: "Can aluminum sheets be laser cut?". The answer is YES, but it's not always simple. Let's explore this technology and how to apply it effectively with aluminum sheets in more detail with Kenta Vietnam in the article below!

What is laser cutting? Why is it so popular?

Laser cutting is a technology that uses a high-power laser beam to melt or vaporize material, thereby creating smooth, almost perfectly precise cuts. For metal materials such as iron, steel, and stainless steel, laser cutting is almost the leading solution due to its extremely high efficiency.

Laser cutting can process many types of materials with different thicknesses, does not cause material deformation, and produces sharp and aesthetic cuts, which is very suitable for high technical requirements in mechanical engineering, electronics, furniture, and construction industries.

Can aluminum sheets be laser cut?

The answer is yes – But suitable conditions are needed

Compared to other metals, aluminum is a material with high light reflectivity and fast thermal conductivity, which makes laser cutting aluminum more difficult. However, with today's modern technology, fiber laser cutting machines can effectively process aluminum sheets.

In particular, high-power laser machines from 1000W upwards will help minimize the risk of burnt edges, reduce slag adhesion, and prevent pitted cuts.

Ideal conditions for laser cutting aluminum sheets

To achieve optimal results when laser cutting aluminum, you should ensure the following conditions:

- Use a high-power fiber laser cutting machine (from 1000W upwards)

- Prioritize high-purity aluminum such as 1050, 3003 or common aluminum alloys such as 5052, 6061

- The thickness of the aluminum sheet should be within the range of 0.5mm to 8mm (depending on machine power)

- The aluminum surface is clean, not too heavily oxidized

Advantages of laser cutting aluminum sheets

1. High precision, beautiful cuts

Laser technology allows cutting aluminum with extremely small errors, usually less than 0.1mm. The cuts are smooth, sharp, and do not require re-grinding, significantly saving post-processing time.

2. Does not deform the material

Aluminum has a high tendency to deform if processed with traditional heat, but with laser cutting – the heat-affected zone (HAZ) is very small, almost not deforming or warping the aluminum sheet.

3. Fast speed, high efficiency

Compared to mechanical or plasma cutting, laser processing is many times faster. For large quantities of aluminum products, this is the optimal solution in terms of both time and cost.

Disadvantages to note when laser cutting aluminum

1. High initial investment cost

High-power fiber laser cutting machines are quite expensive, suitable for large manufacturing enterprises or professional processing facilities. However, the efficiency and quality of the cuts are well worth the investment.

2. High technical operating requirements

To cut aluminum effectively, the operator needs to understand the speed, power, and choose the appropriate shielding gas (usually Nitrogen or Argon to avoid oxidation). Therefore, you should use a reputable processing unit or receive thorough training before using the machine.

Which type of aluminum sheet is best for laser cutting?

Not all types of aluminum are suitable for laser cutting. Here are some common aluminum types suitable for this cutting technology:

- Aluminum 1050:High purity, good thermal conductivity, easy to cut

- Aluminum 5052:Durable, ductile, suitable for furniture, signs, machine casings

- Aluminum 6061:High hardness, widely used in mechanical engineering and automotive

- Aluminum 3003:Good corrosion resistance, reasonable price

At Kenta VietNam, we provide high-quality aluminum sheets of various types, suitable for laser cutting and precision processing. All products have CO-CQ certificates, ensuring high quality and uniformity.