Knowledge, Technology

Does aluminum sheet conduct electricity?

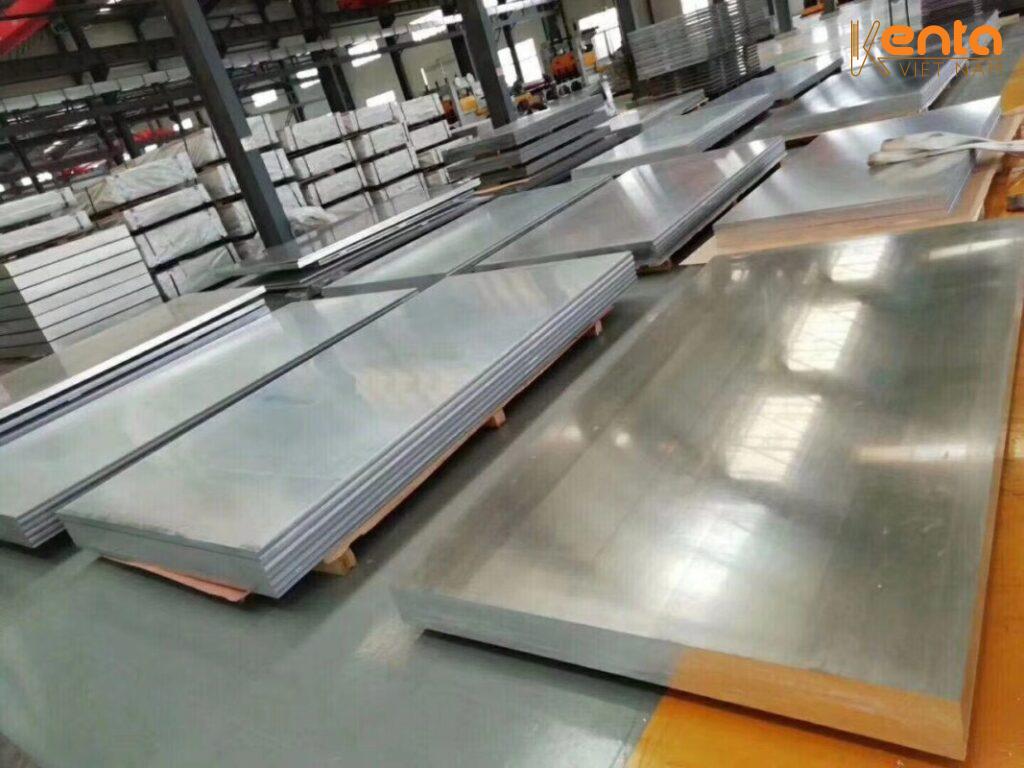

In modern life, aluminum appears everywhere: from construction materials, mechanical engineering, to household electrical devices. But when it comes to conductivity, many people still associate this concept closely with copper. This raises a simple but quite common question: does aluminum sheet conduct electricity?

The question seems small, but if you work in the electrical industry, mechanical manufacturing, or even just want to understand more about this material, it is worth paying attention to. Does aluminum really conduct electricity? And if it does, is it reliable? Let’s dive into the details.

Aluminum is a special metal with electrical conductivity

First, it needs to be affirmed: aluminum is a metal with good electrical conductivity. Although it doesn’t conduct electricity as strongly as silver or copper, aluminum is still highly valued in the electrical industry due to many factors beyond just the pure conductivity index.

When comparing aluminum to copper, it can be seen that aluminum only conducts about 60% as well as copper by the same weight. However, because aluminum is nearly three times lighter, when considering the same volume, aluminum can transmit electricity more efficiently economically and technically.

Especially in industrial environments and long-distance power transmission, people often prefer aluminum to reduce weight, save costs, and still ensure stable electric current transmission.

So what about aluminum sheet? Can aluminum sheet conduct electricity?

The answer is yes. Aluminum sheet can definitely conduct electricity because, in essence, whether in the form of bars, wires, coils, or sheets, aluminum retains its electrical conductivity properties.

In industry, aluminum sheets are used as electrical conductors, heat sinks, or machine parts requiring medium current transmission. If you have seen large electrical cabinets or substations, you have probably noticed large aluminum strips securely bolted to conduct electricity between devices.

Of course, to apply it effectively, it is necessary to carefully calculate the cross-section, thickness, and connection methods. But in principle, there is no reason to doubt the electrical conductivity of aluminum sheet.

Why is aluminum chosen to replace copper in many applications?

You may not have noticed, but nowadays, many electrical wires on poles in rural and suburban areas no longer use copper but have switched to aluminum. The simple reason is that aluminum is cheaper, lighter, and easier to install.

The same goes for aluminum sheets. In many industrial electrical systems, when connecting machine blocks, engineers use aluminum sheets instead of copper to save costs while ensuring safety. If higher conductivity is needed, they just increase the aluminum cross-section a little.

This replacement is not “temporary” but the result of reasonable economic and technical calculations based on decades of practical application.

Does aluminum sheet conductivity have any drawbacks?

Of course, no material is perfect. Although aluminum sheet conducts electricity, there are still a few things to note.

First is the aluminum oxide layer. When exposed to air, the aluminum surface quickly forms a thin oxide film. This layer has excellent corrosion resistance but acts as an insulator. This means if you use aluminum to conduct electricity, you need to clean the surface or use specialized connecting devices to ensure good contact.

Additionally, aluminum is more brittle than copper when bent, and if the connection is not done properly, aluminum joints may become loose after long-term use. However, modern techniques have effectively solved this issue thanks to specialized terminal lugs and cold pressing or friction welding technologies.

What are the common applications of aluminum sheet conductors?

In reality, aluminum sheet conductors are used more than you think. Not only found in large electrical cabinets, aluminum sheets also appear in busbar systems, heat dissipation parts, electrical flanges, or devices that require strong current connections such as transformers, UPS, or solar panels.

Thậm chí trong ngành hàng không và xe điện, nhôm tấm được dùng để chế tạo các bản mạch công suất lớn, vì nó nhẹ, tản nhiệt tốt và vẫn đảm bảo truyền dẫn điện.

Dù bạn là người làm điện dân dụng hay kỹ sư cơ khí, nếu làm việc với dòng điện trung thế hoặc cao thế, bạn sẽ sớm nhận ra tầm quan trọng của loại vật liệu này.

What should be considered when choosing conductive aluminum sheets?

The first important point is to choose the right aluminum grade. If electrical conductivity is a priority, you should use high-purity aluminum grades such as 1050, 1060. These types are softer but conduct electricity much better than harder alloy grades like 6061 or 7075.

Next is the thickness. The thicker the aluminum, the better the conductivity. However, you also need to balance this with the overall size and current load requirements.

Finally, there's the machining factor. If you need pre-cut aluminum sheets, punched holes, or shaped according to drawings, choose a unit capable of precise machining, as even a small error in the screw hole can affect electrical contact.

Where to buy reliable conductive aluminum sheets?

If you need aluminum sheets that can conduct electricity, with sufficient CO – CQ, and detailed advice from choosing the aluminum grade to connection methods, then Kenta Vietnam is a trusted address.

We provide various types of aluminum sheets, especially 1050 – 1060 grades specifically used for conductivity, with thicknesses ranging from 0.5mm to 75mm, fast delivery, precise CNC cutting, and always have technical staff ready to support you from A to Z.

Not just simply selling aluminum, Kenta VietNam accompanies you from the material selection stage to construction, to ensure that each joint and each aluminum sheet achieves optimal efficiency.