Knowledge, Technology

Is aluminum sheet easily deformed when welding?

During the work with aluminum sheets, there is a familiar question that many technicians often ask: “Is aluminum sheet easily deformed when welding?” Many have encountered situations where, after welding, the aluminum sheet is warped, bent, or even lightly cracked near the weld – greatly affecting the aesthetics and technical quality of the product. So what is the truth behind this? And are there ways to limit or control deformation? This article will help you understand the essence of the issue and provide specific solutions.

Physical properties of aluminum

Aluminum is a material highly valued for its light weight, good thermal conductivity, and electrical conductivity. Because of these properties, it is widely used in machinery manufacturing, structural production, shipbuilding, and many other industries. However, these very characteristics make aluminum sheet somewhat more “sensitive” during welding.

When heated, aluminum tends to expand faster than steel. During welding, the arc temperature can reach thousands of degrees Celsius. Concentrating heat in a small area for a short time causes the part of the aluminum near the weld to expand unevenly compared to the rest of the sheet. This uneven expansion is the cause of warping or deformation after welding.

Moreover, aluminum has a relatively low melting point and tends to melt and spread if the current and welding speed are not controlled properly. Therefore, if someone new to working with aluminum applies welding techniques designed for iron or steel as is, it's no surprise to see the sheet get “burned through,” the weld sink in, or even create holes.

Are all aluminum sheets equally prone to deformation?

The answer is no. Not all types of aluminum sheets have the same heat resistance and shape stability. Each aluminum grade has its own physical properties that directly affect its deformation potential when heated.

For example, aluminum 5052 has good ductility and relatively stable heat resistance. It is often chosen for MIG or TIG welding with a lower chance of warping. Meanwhile, aluminum 6061, while stronger, tends to deform more if machine parameters are not properly adjusted.

At Kenta Vietnam, we often advise customers to choose aluminum 5052 sheets for structures requiring flatness or welding thin parts while maintaining strength. For industrial applications demanding higher strength, aluminum 6061 or 5083 would be more suitable – of course, accompanied by technical guidance to control deformation during welding.

What causes deformation during welding? Are there ways to fix it?

In fact, deformation does not come from a single cause. It results from multiple factors acting simultaneously: the thickness of the aluminum sheet, weld joint design, clamping method, welding speed, and the type of current used. If any of these factors is not properly controlled, deformation after welding is entirely possible.

An important point to remember is that aluminum conducts heat very quickly, so the heat-affected zone (HAZ) around the weld is also larger than with steel. This softens the surrounding metal, alters its original structure, and makes it prone to warping as the material shrinks during cooling.

The solution is not to avoid welding but to understand how to weld aluminum correctly to minimize this effect. Breaking the weld into smaller sections, alternating welding from different directions, using positioning bars, or evenly cooling with air are basic techniques that bring significant results.

Is it better to choose thicker aluminum sheets to reduce warping?

Many believe that choosing a thicker aluminum sheet will reduce warping – this is partly true. Clearly, thicker aluminum has a larger mass and better heat absorption, so it deforms less than thinner sheets. However, selecting thicker sheets means higher costs, more difficult machining, and greater welding machine power requirements.

The important thing is to choose a thickness suitable for the product’s technical design, then determine the welding method and adjust the parameters to ensure the weld does not distort the structure.Some manufacturers nowadays tend to tack weld multiple times before performing the main weld to stabilize the shape of the aluminum plate throughout the welding process.

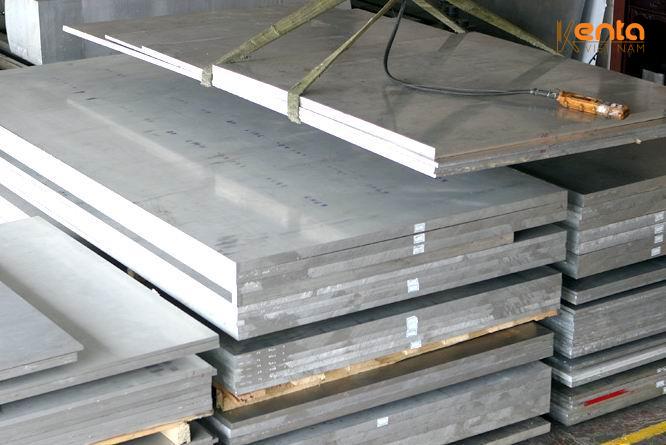

At Kenta, we offer aluminum sheets with thicknesses ranging from 1mm to over 50mm, depending on the needs of each customer. This allows design engineers to flexibly select appropriate materials for each part – from device housings, flanges, machine frames to heavy load-bearing components.

Does the welder’s skill determine the level of deformation?

This cannot be denied. Because with the same type of material and machinery, an experienced aluminum welder will know how to divide the welding path reasonably, time the current interruptions appropriately, and better control the melting heat. Meanwhile, beginners tend to overheat the weld, cause molten weld to spread unevenly or go off track – leading to a wider and harder to control deformation zone.

An important thing to remember is that aluminum conducts heat very quickly, so the heat-affected zone (HAZ) around the weld is wider compared to steel. This causes the surrounding metal to soften, lose its original structure, and easily “follow the momentum” of warping as the material contracts during cooling.

The solution here is not to avoid welding, but to understand the correct way to weld aluminum to minimize this phenomenon. Dividing weld lines into smaller sections, alternating welds from multiple sides, using fixture bars for shaping, or uniformly cooling with gas are basic techniques that bring clear effectiveness.

Should you choose thicker aluminum sheets to reduce warping?

Many people think choosing thicker aluminum sheets will warp less – this is partly true. Obviously, thicker aluminum has more mass, higher heat absorption capacity, so it deforms less compared to thinner sheets. However, choosing thicker sheets means higher cost, more difficult machining, and requires higher welding machine power.

The important thing is to select the thickness suitable for the product’s technical design, then consider welding methods and parameter adjustments to ensure the weld does not distort the structure. Some manufacturers nowadays tend to tack weld multiple times before performing the main weld to stabilize the shape of the aluminum plate throughout the welding process.

At Kenta, we offer aluminum sheets with thicknesses ranging from 1mm to over 50mm, depending on the needs of each customer. This allows design engineers to flexibly select appropriate materials for each part – from device housings, flanges, machine frames to heavy load-bearing components. Kenta VietNam – để đảm bảo mối hàn đạt độ ổn định tốt nhất.

Aluminum sheets can deform during welding, but that’s not a big deal.

If you’re worried that aluminum sheets will warp, twist, or severely deform when welded – then perhaps you haven’t tried welding properly or haven’t used the right type of material. With the right technique, stable skills, and quality materials, you can fully control this phenomenon and produce beautiful, sturdy products that meet technical requirements.

At Kenta VietNam, we provide a full range of aluminum sheets suitable for TIG and MIG welding with various thicknesses, clean surfaces, no warping, and complete COCQ certification. In addition, we are ready to support customers with welding techniques, advice on aluminum grades, selecting welding wires and shielding gases, and connecting with reputable processing workshops if needed.