Knowledge, Technology

Is aluminum sheet easy to machine with CNC?

When it comes to aluminum sheets in mechanical engineering, construction, or interior design, many people are often interested in the cutting and shaping capabilities of this material. One of the most commonly used methods today is CNC machining. So the question arises: is aluminum sheet easy to machine with CNC? Let’s explore this in more detail in the article below.

What is aluminum sheet and what is it commonly used for?

Aluminum sheet is a flat product formed from pure aluminum or aluminum alloy. This material is notable for being lightweight, durable, corrosion-resistant, and especially easy to machine. Depending on the aluminum grade, aluminum sheets can be used to make machine casings, mechanical parts, building facades, partitions, electrical cabinets, aluminum doors, and even furniture and advertising materials.

With the characteristic of being softer than steel but not as brittle as plastic, aluminum sheets allow users to bend, punch, drill, mill, and cut with high precision without breaking or excessively deforming the material. This is why aluminum sheets are very suitable for modern machining methods like CNC.

What is CNC machining and what role does it play in mechanical engineering?

CNC machining is the process of controlling cutting, drilling, turning, milling, or punching machines through a computer. CNC machines can perform extremely precise machining operations according to pre-programmed technical drawings. As a result, the products created have very low errors, sharp and uniform surfaces, and save many manual steps.

For metal materials like aluminum sheets, CNC machining helps cut quickly with clean edges, without melting the edges, reducing burrs, and ensuring nearly absolute accuracy. From the initial aluminum sheets, you can transform them into panel faces, air vents, machine parts, logos, embossed letters, or complex technical components – all within a short time using the appropriate CNC machine.

Is aluminum sheet easy to machine with CNC?

The answer is: very easy.

Not all metal materials are suitable for CNC machines, but aluminum is one of the most ideal materials for this method. Aluminum itself has a softer structure than steel, so the CNC tool can cut, drill, and mill aluminum smoothly without requiring too much force or too slow a speed.

In fact, aluminum is considered a “standard” choice for testing CNC machines because it is easy to cut, easy to test, and causes minimal tool wear. This helps save equipment investment costs and reduces product completion time.

Whether you need to cut logos, drill holes, create grooves, or form complex shapes on aluminum sheets, CNC machines can perform smoothly if programmed correctly and used with the right tools.

Does aluminum sheet require special conditions when processed by CNC?

Although aluminum is easy to machine, to achieve optimal efficiency, you still need to pay attention to some factors before putting aluminum sheets into CNC machines.

First is choosing the appropriate aluminum grade. Soft aluminum types like 1050, 1060 are easier to cut, but if higher mechanical strength is needed, you can choose 5052 or 6061 – two very popular aluminum lines in the industry that are still good for CNC machining.

Next is the thickness of the aluminum sheet. Aluminum that is too thin may vibrate when machined at high speeds, while aluminum that is too thick requires machines with higher power. Typically, CNC workshops handle aluminum sheets best when their thickness ranges from 1mm to 20mm, depending on the machine.

Finally, the aluminum surface should be cleaned before being placed into the machine. Oil, dust, or thick oxide layers can affect the grip of the aluminum sheet on the CNC table and reduce cutting accuracy.

What kind of products does CNC machining of aluminum sheets produce?

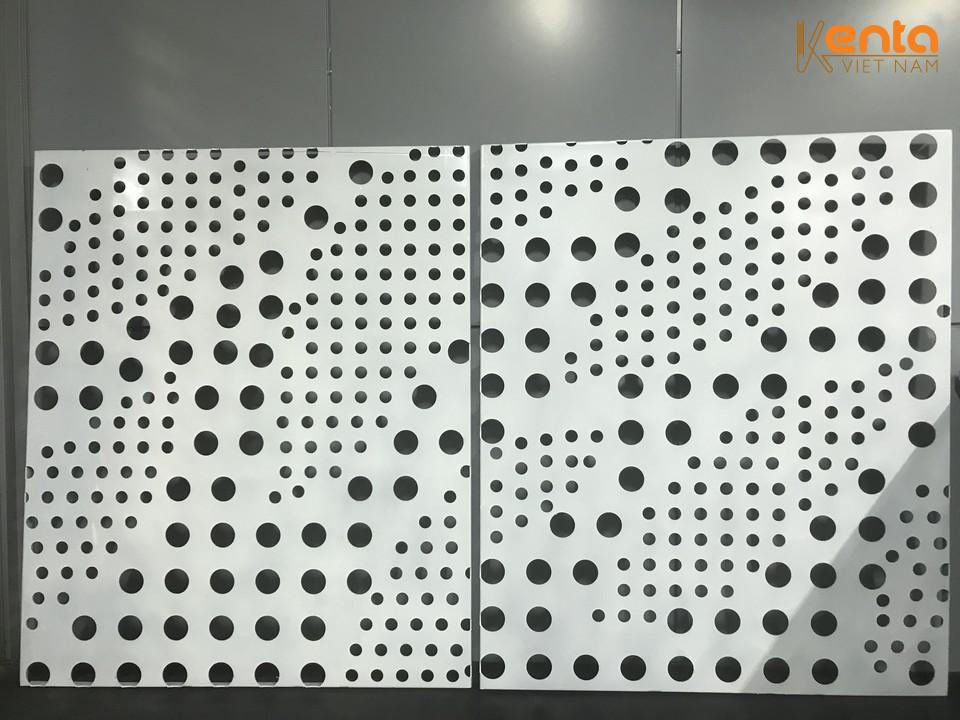

When aluminum sheets are put into CNC machines, the resulting products usually have very high sharpness. The cut lines are smooth, without burnt edges or material deformation. Drilled holes, grooves, or technical grooves are cut exactly according to the original CAD drawings, with errors around ±0.1mm or even lower if the CNC machine is a newer model.

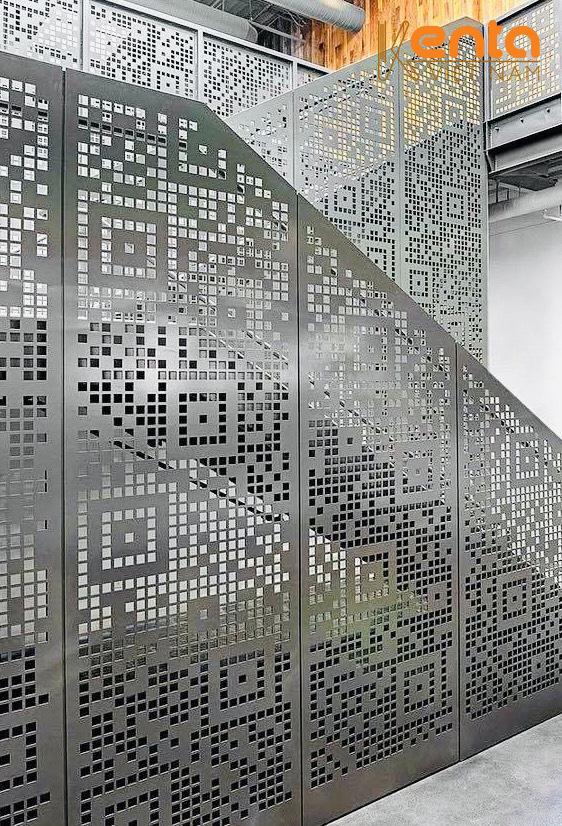

Especially, decorative machining patterns like floral designs, brand logos, embossed letter signs, or decorative panels for ceilings – walls – aluminum gates can all be executed exquisitely. This is why many interior design, advertising, and construction units choose CNC aluminum sheets as the primary material for projects requiring high aesthetics.

Kenta Vietnam – Providing Aluminum Sheets Ready for CNC

If you are looking for aluminum sheets that can be used directly for CNC, or need a supplier that processes aluminum according to drawings, Kenta VietNam is the place you can trust to cooperate with.

At Kenta, we specialize in providing raw aluminum sheets or cutting them to order, with various aluminum grades such as 1050, 5052, 6061thickness ranging from 0.5mm to 75mm. The aluminum sheets are carefully stored, with clean, flat surfaces that meet standards to be put into CNC machines without additional processing.

In addition, Kenta also offers CNC cutting services for aluminum according to drawings, supporting from material consultation to product finishing, helping customers save time and processing costs.

What Fields Use CNC Aluminum Sheets?

Thanks to their flexibility and high precision, CNC processed aluminum sheets are widely applied in many fields. In construction, they are used for curtain walls, sunshades, decorative ceilings. In interior design, they can be used to create patterns for doors, partitions, tables, chairs, handrails. In the electrical-electronics industry, CNC aluminum is often used for machine frames, circuit boards, heat sinks, and technical cabinet enclosures.

Whether for consumer products or industrial equipment, CNC aluminum sheets always bring a modern, sharp look while ensuring technical specifications and long-lasting durability.

Conclusion

In summary, aluminum sheets are among the easiest materials to machine with CNC today. They are not only easy to cut, mill, and drill, but the finished products also achieve high precision, smooth surfaces, and minimal defects.

The important thing is to choose the right type of aluminum, the right thickness, and work with an experienced CNC machining unit to achieve the best results. With such a flexible material as aluminum sheets, you can fully transform complex design ideas into sharp, beautiful, and durable real products.