Knowledge, Technology

Distinguishing Between Solid Aluminum Sheet and Thin Rolled Aluminum Sheet

In the mechanical manufacturing, construction, or shipbuilding industries, aluminum sheets are one of the most commonly used materials thanks to their lightweight, durability, corrosion resistance, and ease of processing. However, not everyone clearly understands that aluminum sheets are divided into many types, with the most common being solid aluminum sheets and thin rolled aluminum sheets. So how can we accurately distinguish these two types? Which one is more suitable for each specific application? This article will help clarify.

What is solid aluminum sheet?

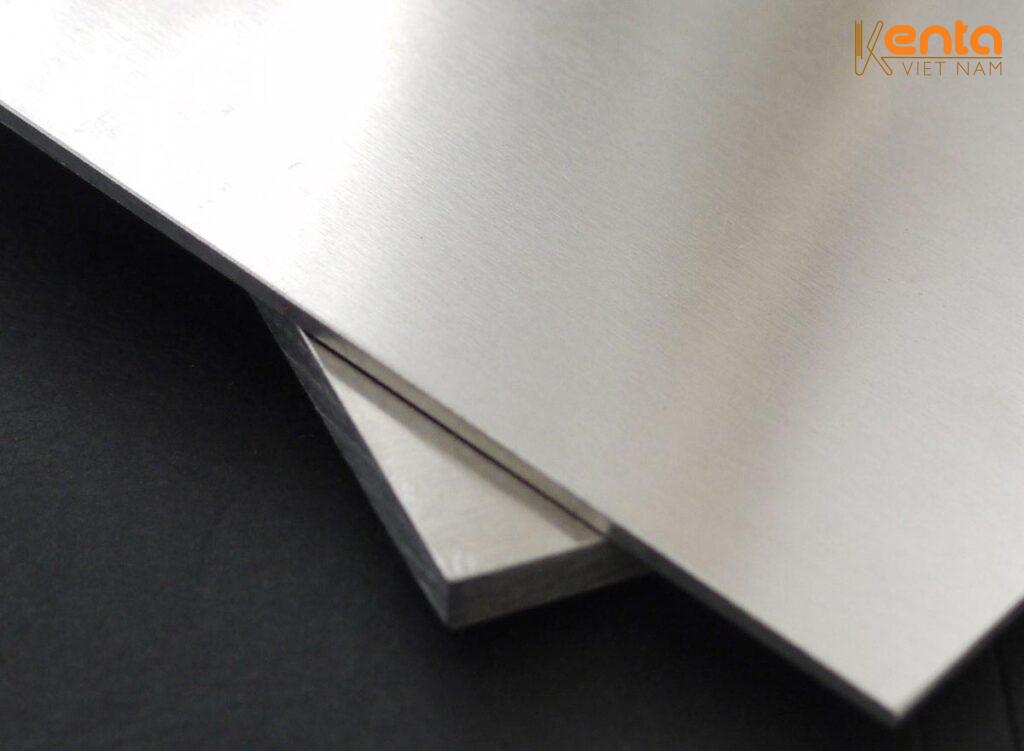

Solid aluminum sheet (also called cast aluminum sheet, extruded aluminum sheet) is produced through a one-time solid casting process or by pressing large blocks and then cutting them into sheets according to requirements. A noticeable feature of this type of aluminum is its large thickness, usually from 10mm to 100mm or more, depending on the application. The surface of solid aluminum may not be as smooth as rolled aluminum, but in exchange, it has a solid structure, minimal deformation, and especially high load-bearing capacity.

This type of aluminum is often used in the mechanical manufacturing sector, mold making, machine bases, or parts requiring extremely high strength. Due to its mechanical stability, solid aluminum is very popular in fields needing materials that withstand heavy loads, operate in strong vibration environments, or endure significant impacts.

What is thin rolled aluminum sheet?

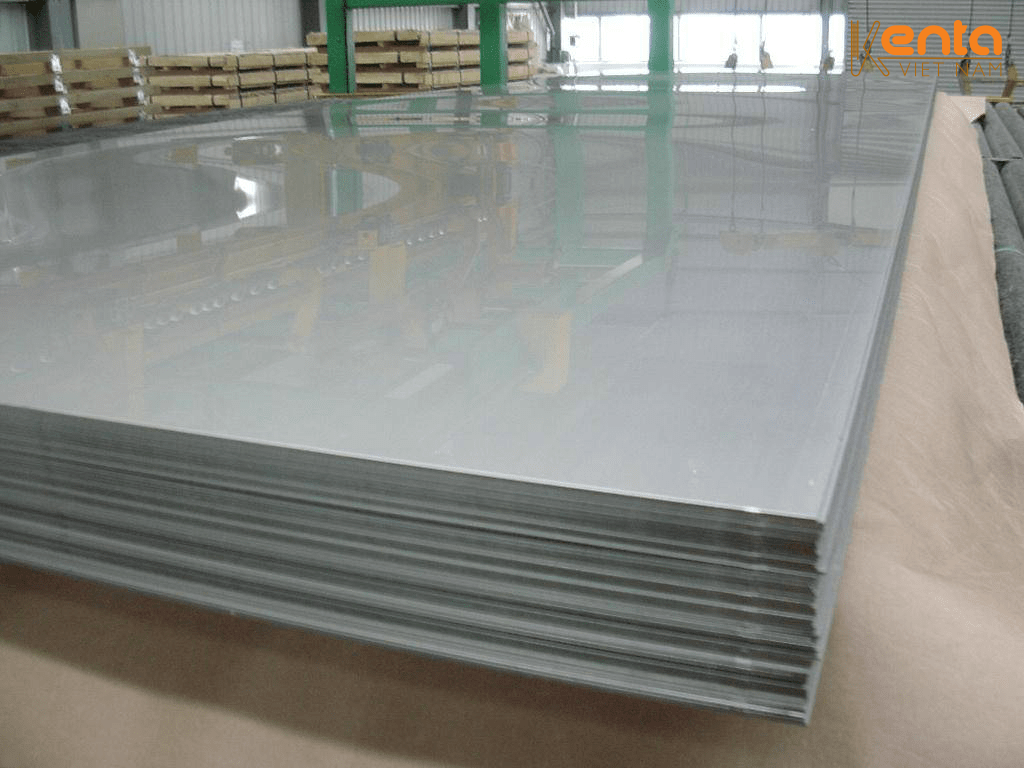

Conversely, thin rolled aluminum sheet is produced by repeatedly rolling flat large aluminum billets, making the material thinner – usually from 0.3mm to about 10mm. Because it is continuously rolled, the surface of this aluminum type is smooth, shiny, and uniform, making it very suitable for applications requiring high aesthetics or easy bending and shaping, such as advertising, packaging, interior design, or electronics.

Thin rolled aluminum may also be an aluminum alloy, but its mechanical properties are lower than those of solid aluminum due to its thin structure and less density. However, its strengths lie in being lightweight, easy to transport, easy to cut, easy to process, and cheaper in cost, so it’s very suitable for mass production, medium to light parts, or structures that do not bear too much load.

Distinguishing solid aluminum sheets from thin rolled aluminum sheets – based on what?

Differences in production processes are one of the clearest points to distinguish between these two types of aluminum. Solid aluminum undergoes casting or pressing under high pressure, then surface treatment and cutting into sheets. Meanwhile, thin rolled aluminum must go through many continuous cold rolling or hot rolling stages to achieve the required thinness. This difference creates clear variations in density, material compactness, and physical and mechanical properties.

Differences in thickness and mechanical strength: when comparing thickness, solid aluminum clearly holds an advantage with thicknesses reaching several tens of millimeters, suitable for projects requiring load-bearing or deep processing. Thin rolled aluminum is usually used in light parts, decoration, or products that do not demand much tensile strength. Thanks to its solid structure, solid aluminum is less prone to warping during processing and better maintains its shape in vibrating environments, high temperatures, or high pressure.

Workability and surface aesthetics. In terms of aesthetics, thin rolled aluminum sheets are often rated higher due to their flat, uniform, and glossy rolled surface. This is an ideal choice for parts requiring aesthetics such as wall cladding, doors, signboards, lighting frames… As for solid aluminum, the surface may be rougher due to less rolling but can be treated by polishing or anodizing.

Thin rolled aluminum’s workability is better in bending, cutting, punching, and stamping shaping steps. Meanwhile, solid aluminum is more suitable for CNC turning, milling, or mold making thanks to its ability to maintain hardness well during processing.

Cost and usage expenses cannot be ignored when distinguishing these two types of aluminum. Thin rolled aluminum, thanks to its mass production process and thickness under 5mm, is considerably cheaper. This helps optimize costs when used for products that do not need to bear heavy loads. Solid aluminum, on the other hand, has a higher price,but in return brings long-lasting effectiveness for projects that require absolute firmness and stability.

Practical applications of each type

When should you choose solid aluminum plate?

If you work in the field of mold making, CNC machine bases, load-bearing structures, or industrial ships, solid aluminum is an irreplaceable choice. With its thick, hard, and durable characteristics, solid aluminum ensures the stability of the entire system, minimizing risks of warping or material fatigue over a long period.

When should you choose thin rolled aluminum plate?

For advertising projects, interior design, aluminum glass doors, electrical cabinets, partitions, or light boxes, thin rolled aluminum plate is more suitable due to its lightness, beauty, ease of installation, and ease of processing. You can easily cut it with CNC shears, fold edges by hand or machine, paint or print logos on the surface. The price of this type is also “softer”, making it suitable for mass production.

So which type should you choose?

The choice between solid aluminum and thin rolled aluminum depends entirely on your specific use. If the project leans toward technical structure and load-bearing – prioritize solid aluminum. If aesthetics, easy processing, and cost savings are the priority – thin rolled aluminum is a more reasonable solution.

In many cases, large enterprises still combine both materials in one system: using solid aluminum for the load-bearing frame, while the outer cladding uses thin rolled aluminum to save costs and ensure aesthetics.

Understand correctly to use correctly – Kenta Vietnam

Kenta VietNam is a distributor offering a diverse range of aluminum plates, from 1050, 5052, 5083 to specialized solid aluminum, complete with CO-CQ, VR registration, in-stock items sized to order, and fast nationwide delivery.

We not only sell materials but also provide dedicated technical consultation to help you choose the right aluminum – the right application – the right cost.