Knowledge, Technology

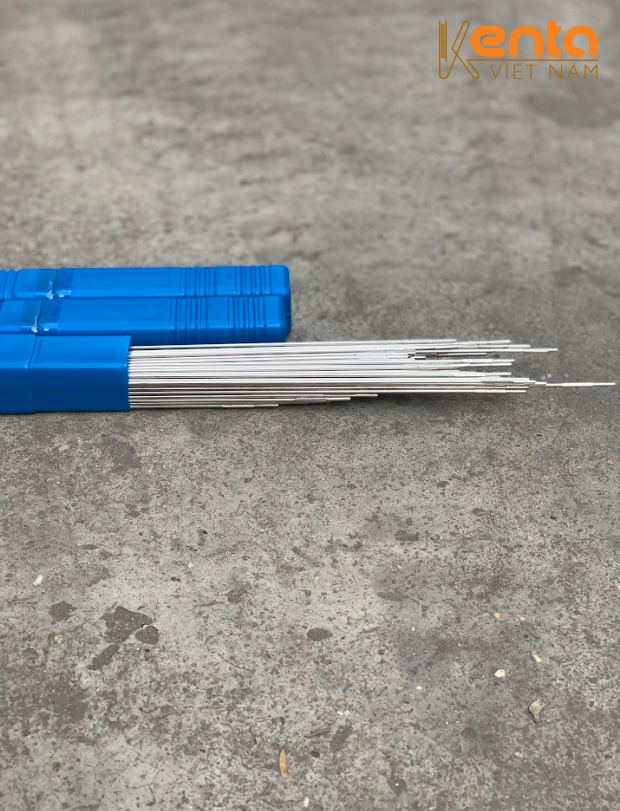

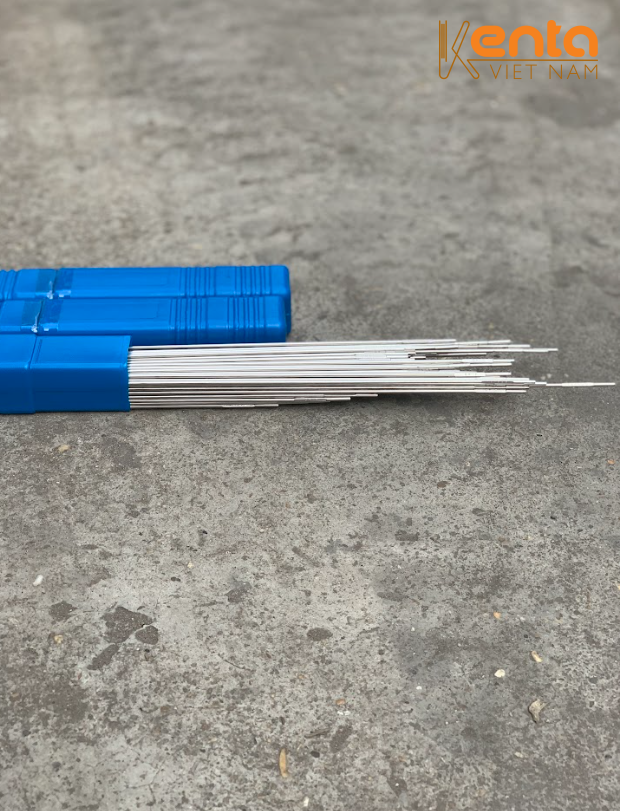

STAINLESS STEEL WELDING RODS – WELDING MATERIALS WITH HIGH APPLICABILITY IN DAILY LIFE AND INDUSTRY

Stainless steel welding rods are one of the important products in the welding industry, especially when working with stainless steel materials. Kenta Vietnam will provide detailed information about stainless steel welding rods, from characteristics, how to choose, to applications and benefits of use in the following article.

Stainless steel welding rods – Welding materials with high applicability in daily life and industry

What are stainless steel welding rods?

They are a type of welding rod made from stainless steel alloy (inox), containing main components such as chromium, nickel, and molybdenum. These components not only give the welding rod high corrosion resistance but also provide aesthetic appeal and superior durability to the weld.

Stainless steel welding rods are often used in applications requiring welds with oxidation resistance, good load-bearing capacity, and hygiene, such as in the food, chemical, and construction industries.

Classification of stainless steel welding rods

Classified based on composition and application, the most common types include:

- Stainless steel welding rods 308: Suitable for 18/8 stainless steel or 304 stainless steel. This is the most common type of welding rod with good corrosion and oxidation resistance.

- Stainless steel welding rods 316: Used for 316 stainless steel and other molybdenum-containing stainless steels. This type of rod is particularly suitable for acidic or strong chemical environments.

- Stainless steel welding rods 309: Used for welding different materials such as stainless steel to ordinary steel, thanks to its good connection capability between different metals.

Classification of stainless steel welding rods

How to choose the right stainless steel welding rod

To ensure weld quality, choosing the right welding rod is extremely important. You need to consider the following factors:

- Type of material to be welded::

- Determine the type of stainless steel or inox to be welded to choose a welding rod with corresponding components.

- For materials exposed to harsh environments, prioritize welding rods containing molybdenum (such as 316 stainless steel).

- Material thickness::

- The welding rod needs to have a diameter suitable for the material thickness. The common diameter of stainless steel welding rods usually ranges from 2.0mm to 5.0mm.

- Environment of weld use::

- In highly corrosive environments or extreme temperatures, choose a welding rod with high strength and corrosion resistance.

- Brand and origin::

- Prioritize using welding rods from reputable brands to ensure weld quality and minimize risks.

Welding process with stainless steel welding rods

Using the welding rod correctly will help ensure high-quality welds. The basic welding process includes:

- Surface preparation of the material::

- Clean the material surface by removing dust, grease, or rust to ensure the weld adheres firmly.

- Select welding current::

- Adjust the welding current to suit the welding rod diameter and material thickness.

- Proceed with welding::

- Weld at a steady speed, maintaining a consistent distance between the welding rod and the material to ensure a uniform weld, free from porosity or slag inclusions.

- Inspect the weld::

- After welding, inspect the weld for strength, smoothness, and aesthetic appeal.

Welding process with stainless steel welding rods

Advantages of using stainless steel welding rods

Using welding rods offers many benefits, including:

- High corrosion resistance::

- Chromium in stainless steel creates a protective layer against oxidation, making the weld durable in harsh environments.

- High aesthetics::

- Stainless steel welds are shiny, do not require painting, and are easy to clean, which is especially important in the food and medical industries.

- Superior durability::

- The weld has good load-bearing capacity, ensuring a long lifespan for structures and equipment.

- Easy to process::

- Stainless steel welding rods are flexible and easy to use on various types of materials.

Applications of stainless steel welding rods in daily life and industry

Widely applied in many fields such as:

- Food industry:Welding storage tanks, pipelines, and food processing equipment to ensure hygiene and safety.

- Chemical industry:Used in systems containing corrosive chemicals or acids.

- Shipbuilding industry:Welding components exposed to seawater.

- Construction:Used in constructions requiring high durability and aesthetic appeal.

Notes on storing stainless steel welding rods

To ensure the quality of welding rods, you need to store them correctly:

- Place welding rods in a dry place, cool and dry to avoid mold or rust.

- Store in original packaging if not yet used.

- Avoid contact of welding rods with corrosive chemicals.

Notes on storing stainless steel welding rods

Conclusion

Stainless steel welding rods are the perfect solution for projects requiring high-quality, durable, and aesthetically pleasing welds. Choosing and using stainless steel welding rods correctly not only improves work efficiency but also saves costs in the long run.

We hope this article has provided you with comprehensive information to better understand stainless steel welding rods and how to use them effectively. Learn more at Kenta Vietnam for more information on welding materials!