Knowledge, Technology

Applications of aluminum sheets in construction

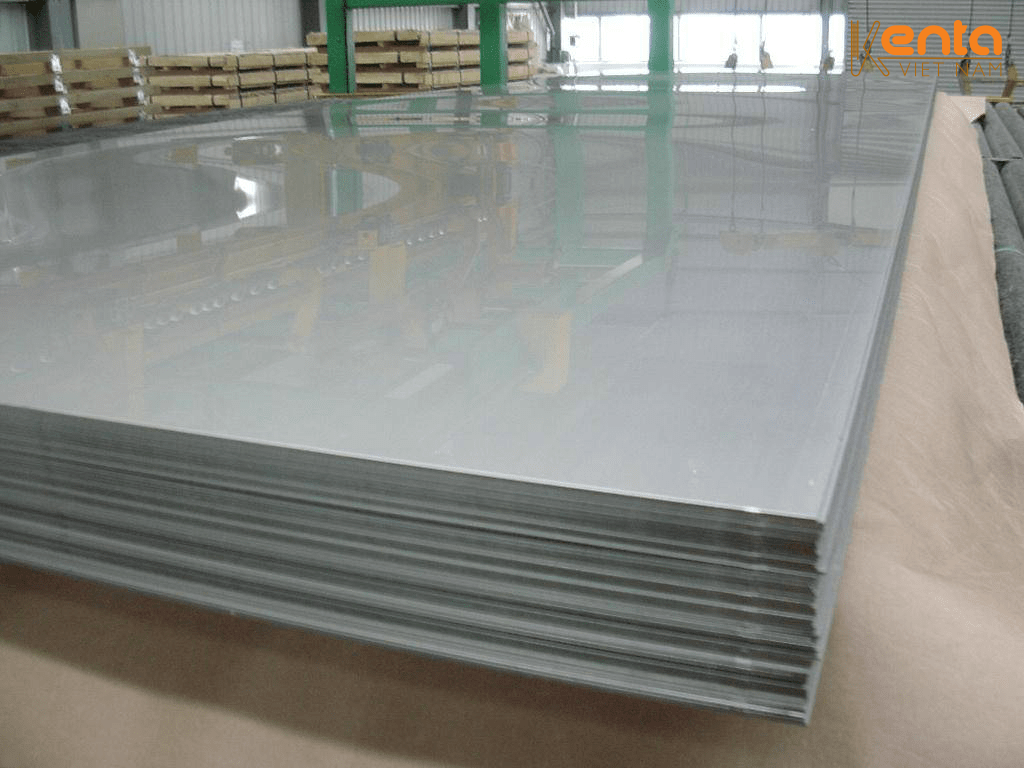

Modern construction not only requires durable materials but also demands flexibility, aesthetics, and environmental friendliness. Among the many commonly used materials, aluminum sheets are gradually affirming their important position thanks to outstanding advantages in weight, corrosion resistance, ease of installation, and diverse applications.

From high-rise building facades to canopies, aluminum doors, or lightweight structural systems, aluminum sheets appear everywhere in modern architectural projects. This article will help you clearly understand the applications of aluminum sheets in construction.

Aluminum sheets: an important material in the construction industry

When talking about aluminum sheets, many people immediately think of lightness, brightness, and ease of installation – and these are very beneficial characteristics in the construction field. Compared to steel or traditional materials, aluminum has a specific gravity of only about 2.7 g/cm³, which is nearly 3 times lighter than steel. This means reducing the load for the structure, which is especially important for high-rise projects, prefabricated houses, or suspended structures.

Despite being light, aluminum still ensures high rigidity and tensile strength, especially alloy aluminum types like 5052, 5083, or 6061 – commonly used in construction details that require good load-bearing capacity.

Moreover, the surface of aluminum sheets can be treated by various techniques such as anodizing, powder coating, polishing, which help increase durability and enhance the aesthetic value of the project.

Corrosion resistance: a big plus for harsh environments

In construction, exposure of materials to sun, rain, humidity, seawater, or chemicals is unavoidable. This is when aluminum sheets demonstrate their natural corrosion resistance, unmatched by many other materials.

When exposed to air, aluminum forms a very thin but durable oxide layer (Al₂O₃) that prevents the penetration of moisture, saltwater, or mild acids. Thanks to that, aluminum sheets are less likely to rust, do not peel off like steel, and do not require continuous maintenance – saving time and costs for investors.

Therefore, aluminum sheets are an ideal choice for coastal constructions, chemical plants, cold storage, outdoor projects, or areas with high humidity.

Easy to install, shortening construction time

In the context of the construction industry increasingly tightening timelines and budgets, using easy-to-install materials like aluminum sheets is a smart solution.

Aluminum has good ductility, easy to bend, easy to cut with laser machines, CNC, or conventional mechanical machines. With stable hardness and light weight, large aluminum sheets can be transported and installed quickly without needing overly complex specialized equipment.

Additionally, the ability to be screwed, welded, connected by rivets or sliding rails helps aluminum sheets easily adapt to various structures – from facade systems, domed roofs, partitions to detailed parts such as windows, doors, wall cladding, and more.

All of these features help shorten construction progress, reduce labor, and limit technical errors during installation.

High aesthetics and flexible architectural design

Nowadays, construction projects need not only durability but also beauty. With a bright surface and ease of color processing, aluminum sheets offer many aesthetic options for architects and designers.

Through treatment methods like colored anodizing, powder coating, wood grain texture, or pattern printing on aluminum, aluminum sheets can transform into many styles, suitable for everything from modern to classic aesthetics.

Thanks to that, this material is widely applied in highly decorative categories such as: facade cladding, interior decorative partitions, artistic sunshades, aluminum suspended ceilings, or public projects like shopping centers, stations, and airports.

Specific applications of aluminum sheets in construction

Aluminum curtain wall systems are the most common use of aluminum sheets. These aluminum panels are usually anodized or powder-coated, assembled in modular forms that create flexible shapes for building facades while enhancing thermal insulation and noise reduction.

Canopies, aluminum ceilings, sunshades, with anti-rust, heat-resistant, and lightweight properties, aluminum sheets are used for terrace canopies, station roofs,Aluminum hanging panels or decorative sunshades – both aesthetic and protective against harsh weather conditions.

Aluminum and glass door systems, aluminum profile sheets used to fabricate door frames, windows, and curtain wall facades are very popular in Vietnam. The advantages include high durability, no warping, easy cleaning, and especially suitability for tropical climates.

Stairs, railings, fences – due to their light weight and strong load-bearing capacity, aluminum sheets are also used to manufacture spiral stairs, emergency stair treads, balcony railings, villa fences… enhancing aesthetic value while ensuring safety.

Partitions, wall cladding, recessed electrical cabinets – in high-end industrial or civil projects, aluminum sheets are CNC cut to make room partitions, toilet partitions, recessed electrical cabinets, or artistic aluminum wall cladding, which are both beautiful, easy to clean, and resistant to moisture and mold.

Aluminum sheets: a green solution for modern construction

In the trend of “greening” the construction industry, aluminum sheets are environmentally friendly materials because they can be recycled almost 100% without quality loss. Used aluminum sheets can be melted, refined, and remade into new products while retaining their mechanical properties.

Not only does this reduce construction waste, but using aluminum also decreases building weight, saves transportation fuel, saves cooling energy, thereby contributing to reduced carbon emissions and long-term operating costs. With recyclability, sustainability, and long lifespan, aluminum sheets are a suitable material choice for projects aiming for sustainable development.

Aluminum sheets: a smart choice for the construction industry

From corrosion resistance, lightweight, durability, ease of processing, high aesthetics to environmental friendliness, aluminum sheets are a top choice in many modern construction projects. Not only do they help optimize costs and shorten construction time, but aluminum sheets also bring long-lasting value in terms of quality and aesthetics.

If you are looking for a source of high-quality aluminum sheets at reasonable prices, with a variety of aluminum grades like 5052, 5083, 6061, 1100,… complete certification (COCQ, VR registration, clear origin), contact Kenta Vietnam immediately.