Knowledge, Technology

Advantages of Aluminum Sheets in Mechanical Manufacturing

In the modern industrial world, choosing the right material is vital for any product or processing operation. Among the many materials used today, aluminum sheets stand out as a flexible, efficient, and economical choice for the mechanical manufacturing industry. Not only because of their light weight, aluminum sheets also possess many superior technical advantages that optimize both performance and cost.

So why are aluminum sheets favored in the mechanical industry? And what are the advantages of aluminum sheets in mechanical manufacturing? Let’s take a deeper look in this article.

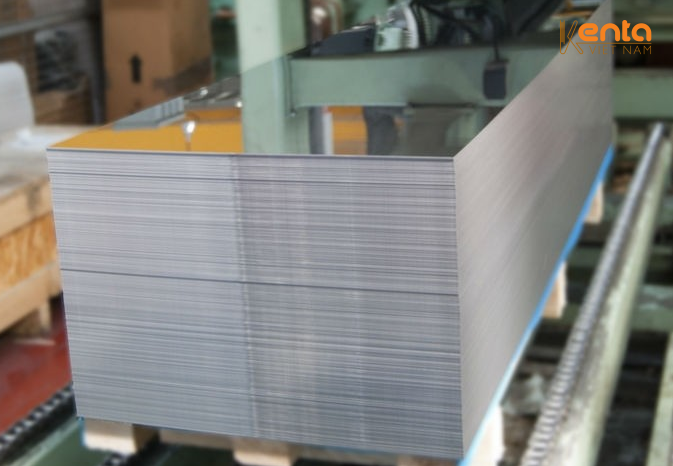

Aluminum Sheets – “Lightweight but Heavy in Role” Material

In mechanical fabrication, an ideal material needs not only to be durable but also easy to work with, easy to shape, cost-effective, and safe during use. Aluminum sheets are among the few materials that can meet most of these criteria.

With a density of about 2.7 g/cm³, aluminum sheets are nearly 3 times lighter than steel. This offers a significant advantage when producing large mechanical parts or applications in transportation – where weight is a crucial factor.

Although light, aluminum still maintains tensile strength and stable load-bearing capacity, especially in alloy grades like 5052, 6061, or 5083. This allows aluminum sheets to be used for load-bearing components, machine parts, or mechanical molds.

Easy to Process, Time and Cost Saving

One of the biggest plus points of aluminum sheets in the mechanical field is their outstanding processability. Aluminum is highly ductile, easy to cut, punch, bend, or weld. This helps shorten fabrication time and reduces the strain on machinery during processing.

Compared to steel, cutting aluminum sheets by laser, CNC, or hand saw is faster and causes less tool wear. Especially in small and medium mechanical workshops, using aluminum helps decrease equipment maintenance costs, thereby improving overall operational efficiency.

Moreover, aluminum also allows easy surface treatment by methods such as anodizing, powder coating, or polishing, which helps increase product durability and aesthetic appeal.

Natural Corrosion Resistance is a Major Advantage

When exposed to air, aluminum quickly forms a very thin but extremely durable oxide layer (Al₂O₃). This layer acts as a “shield” protecting the aluminum surface from moisture, chemicals, or environmental corrosive agents.

Therefore, aluminum sheets are widely used in outdoor applications, marine environments, chemical industries, or precision mechanical fields that require high durability. Unlike iron or steel that must be continuously coated to prevent rust, aluminum requires almost no maintenance, thus saving maintenance costs for businesses.

Aluminum Sheets Reduce Weight While Maintaining Strength

In modern mechanics, reducing product weight is an inevitable trend – especially in industries like aerospace, transportation, automotive, or industrial robotics. Thanks to their light weight, aluminum sheets help reduce the load on the entire machinery system, increase operational efficiency without sacrificing stiffness or product safety.

As a result, many factories have gradually switched from using steel to aluminum sheets for parts such as machine frames, fixtures, ladders, structural components, robotic arms, or industrial electrical cabinets.

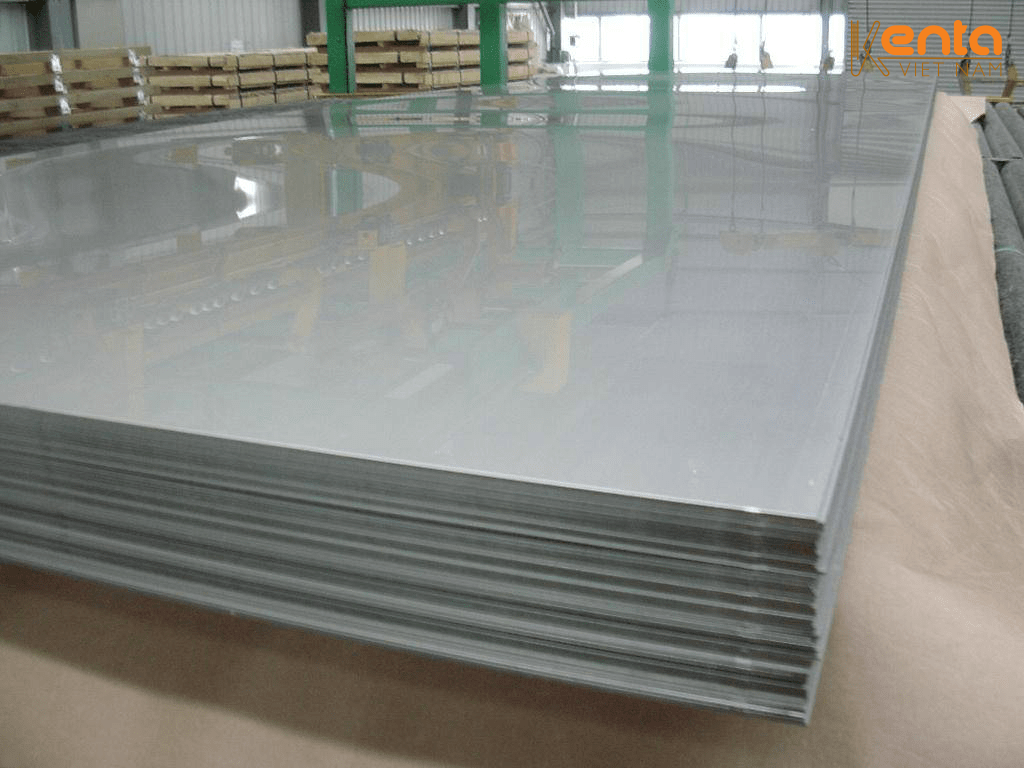

High Aesthetic Value, Easy Surface Finishing

Besides technical factors, aesthetics is also an important requirement in modern mechanics – particularly for exposed parts, machine cabinets, public equipment, or export products.

Aluminum sheets have naturally smooth surfaces that are easy to handle, facilitating finishing techniques such as painting, plating, polishing, or anodizing. This not only enhances aesthetics but also improves corrosion resistance and extends product lifespan.

For demanding customers, aluminum sheets enable the creation of products that are both sturdy and visually appealing, with uniform color and easy cleaning—features that many other metals find difficult to match simultaneously.

Environmentally Friendly – Nearly 100% Recyclable

Another notable point is that aluminum can be recycled almost entirely without losing quality. In the context of the mechanical engineering industry gradually "greening" production and complying with low emission standards, aluminum sheets become the ideal choice for businesses aiming for sustainable development.

The aluminum recycling process consumes much less energy compared to primary metallurgy, while also helping reduce industrial waste. This is not only good for the environment but also helps businesses save on material costs in the long run.

Practical Applications of Aluminum Sheets in Mechanical Production

With all the advantages mentioned above, aluminum sheets have been widely applied in many mechanical manufacturing segments. From manufacturing molds, machine casings, structural frames, workbenches, technical ladders, electrical cabinets to components in automation, shipbuilding, aviation, and agricultural machinery manufacturing, aluminum sheets clearly demonstrate superior efficiency and durability.

In addition, premium aluminum sheet grades such as 5052, 5083, 6061 are also used for machining precise mechanical molds, medical equipment, or export products requiring strict technical standards. This shows that aluminum sheets are not only common materials but also strategic materials in the modern mechanical industry.

Aluminum Sheets – The Ideal Material for Modern Mechanics

Easy to process, lightweight, corrosion-resistant, attractive, and environmentally friendly – all these advantages make aluminum sheets the optimal choice in mechanical production. Whether you run a small workshop or a large-scale factory, aluminum sheets can flexibly meet all demands – from single products to mass production.

If you need advice on selecting the right aluminum grade, sourcing high-quality aluminum sheets with full certifications (COCQ, VR, origin from EU, China, Korea…), please contact understanding this, Kenta Vietnam. Kenta VietNam.