Knowledge, Technology

What is aluminum forging? Applications of aluminum forging

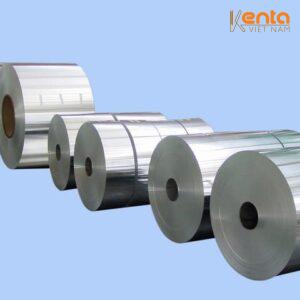

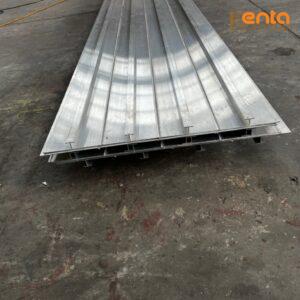

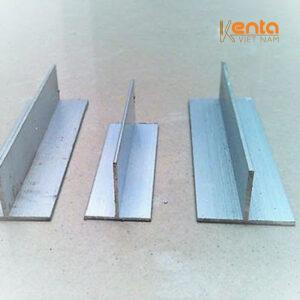

Aluminum forging, also known as forging, is a metalworking process in which aluminum is heated and shaped under pressure to create products of desired shapes and sizes. This process typically involves heating aluminum to a high temperature, then using tools such as hammers, dies, or presses to compress and shape the aluminum.

1. Aluminum Forging Process

a. Types of Forging

- Hot ForgingAluminum is heated to a high temperature (usually above 400°C) to make the metal softer and easier to shape. This process helps improve the mechanical properties of the product and reduces the force required for shaping.

- Cold ForgingAluminum is processed at room temperature. This method typically requires greater force and can cause stress in the material. Cold forging is mainly used for small and thin products.

b. Implementation Process

- Heating (for Hot Forging):Aluminum material is heated to the required temperature to increase ductility and reduce hardness.

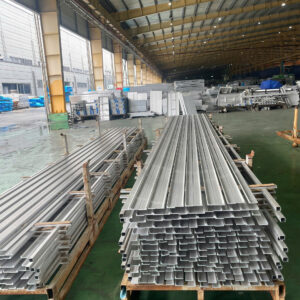

- Material Preparation:Aluminum is cut into blocks or bars of appropriate size.

- Shaping:Aluminum is compressed or hammered in a die to create the desired shape. Presses, hammers, or other equipment may be used.

- Cooling and Treatment:After shaping, the product is slowly cooled to reduce stress and increase durability.

c. Advantages of Aluminum Forging

Ability to Create Complex Shapes:Can create complex shapes and large sizes without much additional processing.

Increased Strength:The forging process helps improve mechanical strength by creating a more uniform crystal structure and eliminating defects.

High Precision:Forged products often have higher precision compared to other processing methods.

2. Industrial forging process (FORGING)

Basically, the operations of the forging method include upsetting, punching, bending, cutting, and drawing.

– Upsetting is to increase the cross-sectional area of the workpiece and reduce its height. When upsetting, only a part of the head or middle of the workpiece may need to be heated to change the cross-section.

– Punching is the process of creating holes or deep depressions in the workpiece.

– Bending is to change the fiber direction of the workpiece.

– Cutting is to cut the workpiece into sections.

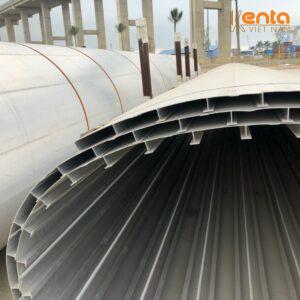

– Drawing is used when wanting to lengthen the workpiece, reducing the cross-sectional area of the workpiece. It is possible to flat draw to flatten the workpiece, wide draw a hole to increase the diameter of the pipe, or long draw a pipe using a central axis to increase the length of the pipe and simultaneously reduce the thickness of the pipe.

3. Applications of aluminum forging

Very diverse and important in many industries, including:

- Aerospace industry:Aluminum is widely used in aircraft and spacecraft components due to its light weight and good load-bearing capacity. Components such as aircraft frames, wings, and structural components of spacecraft are often manufactured using aluminum forging to ensure high strength and precision.

- Automotive industry:Engine parts, suspension systems, and other structural components in automobiles are often manufactured by forging aluminum to reduce weight and increase performance.

- Electronics industry:Forged aluminum is used in electronic devices such as computer casings and components of other electronic devices due to its good electrical conductivity and effective heat dissipation.

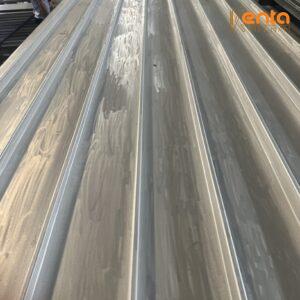

- Construction industry:Construction products such as door handles, window frames, and decorative details can be manufactured by aluminum forging, thanks to aluminum's durability and corrosion resistance.

- Sports and entertainment industry:Sports equipment such as bicycle frames, skateboards, and other sports accessories often use forged aluminum to combine durability with light weight.

The forging process helps improve the mechanical strength of aluminum compared to other processing methods, as it creates more uniform crystal structures and eliminates defects.

Contact information:

KENTA VIETNAM TECHNICAL CO., LTD

![]() Head office: No. 22, Phung Cong Service Area, Phung Cong Commune, Hung Yen Province

Head office: No. 22, Phung Cong Service Area, Phung Cong Commune, Hung Yen Province

![]() Hotline/Zalo: 0961909992

Hotline/Zalo: 0961909992

![]() Email: contact@kentavietnam.com

Email: contact@kentavietnam.com

![]() Website: kentavietnam.com

Website: kentavietnam.com